At Home Owners Association, we understand the importance of protecting your property from water damage. Bituminous waterproofing membrane is a powerful solution for safeguarding your home’s foundation and structure.

This guide will walk you through the process of applying this effective waterproofing material, ensuring your home stays dry and secure for years to come.

What Are Bituminous Waterproofing Membranes?

Bituminous waterproofing membranes are robust, flexible sheets that form a powerful barrier against water infiltration. These membranes protect buildings and structures from moisture damage, making them an essential component in construction and renovation projects.

Composition and Types

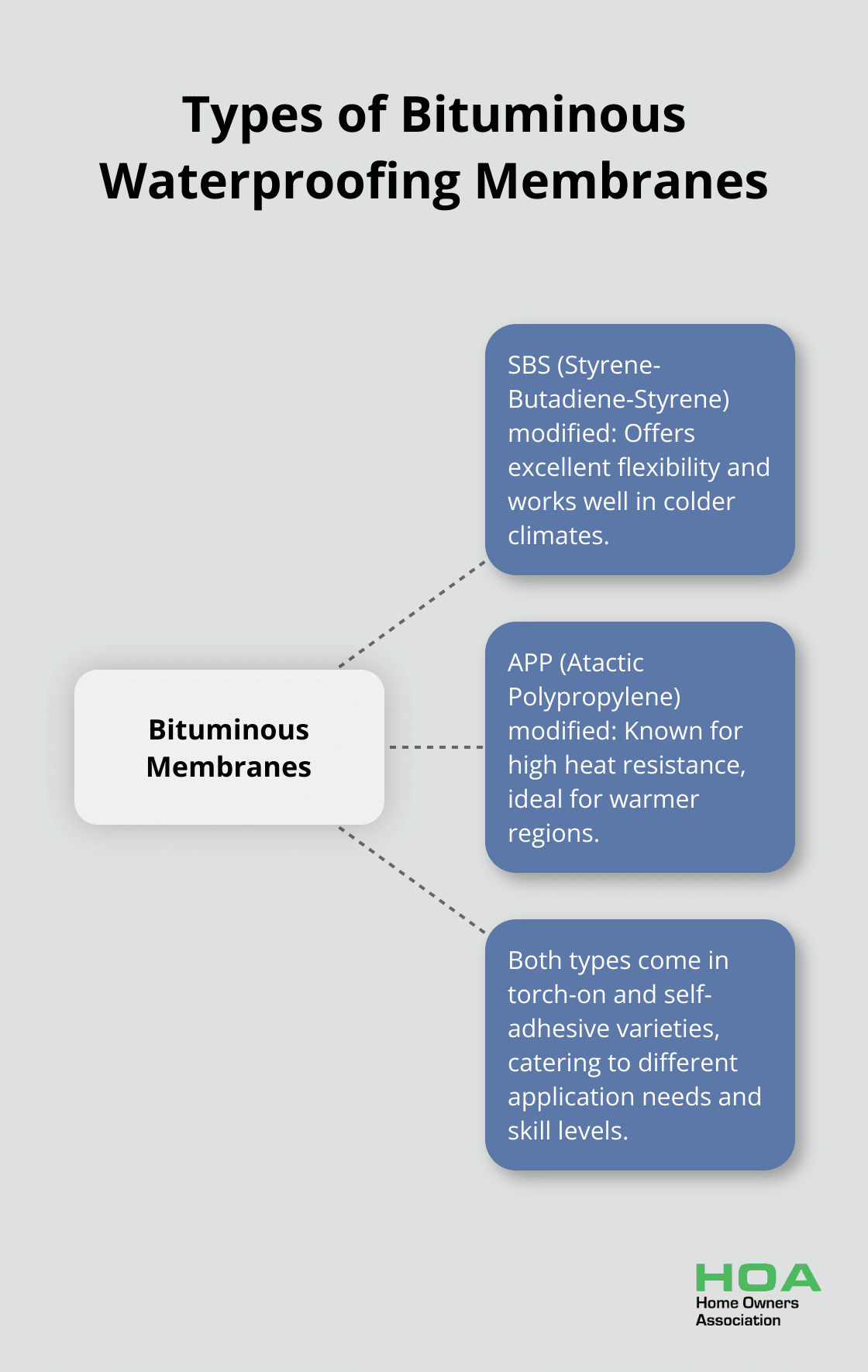

The core of a bituminous membrane consists of modified bitumen mixed with polymers to enhance its properties. This combination results in a material that’s both durable and flexible. The two main types of bituminous membranes are:

- SBS (Styrene-Butadiene-Styrene) modified: These membranes offer excellent flexibility and work well in colder climates.

- APP (Atactic Polypropylene) modified: Known for their high heat resistance, these are ideal for warmer regions.

Both types come in torch-on and self-adhesive varieties, catering to different application needs and skill levels.

Advantages of Bituminous Waterproofing

Bituminous membranes have gained popularity due to their numerous benefits. They resist UV radiation effectively (a key feature in sunny climates) and withstand temperature fluctuations, making them suitable for diverse weather conditions.

Bituminous membranes are perfect for waterproofing roofs, basements, below-ground structures, bridges and other structures. This versatility underscores their reliability and effectiveness in various applications.

Application and Longevity

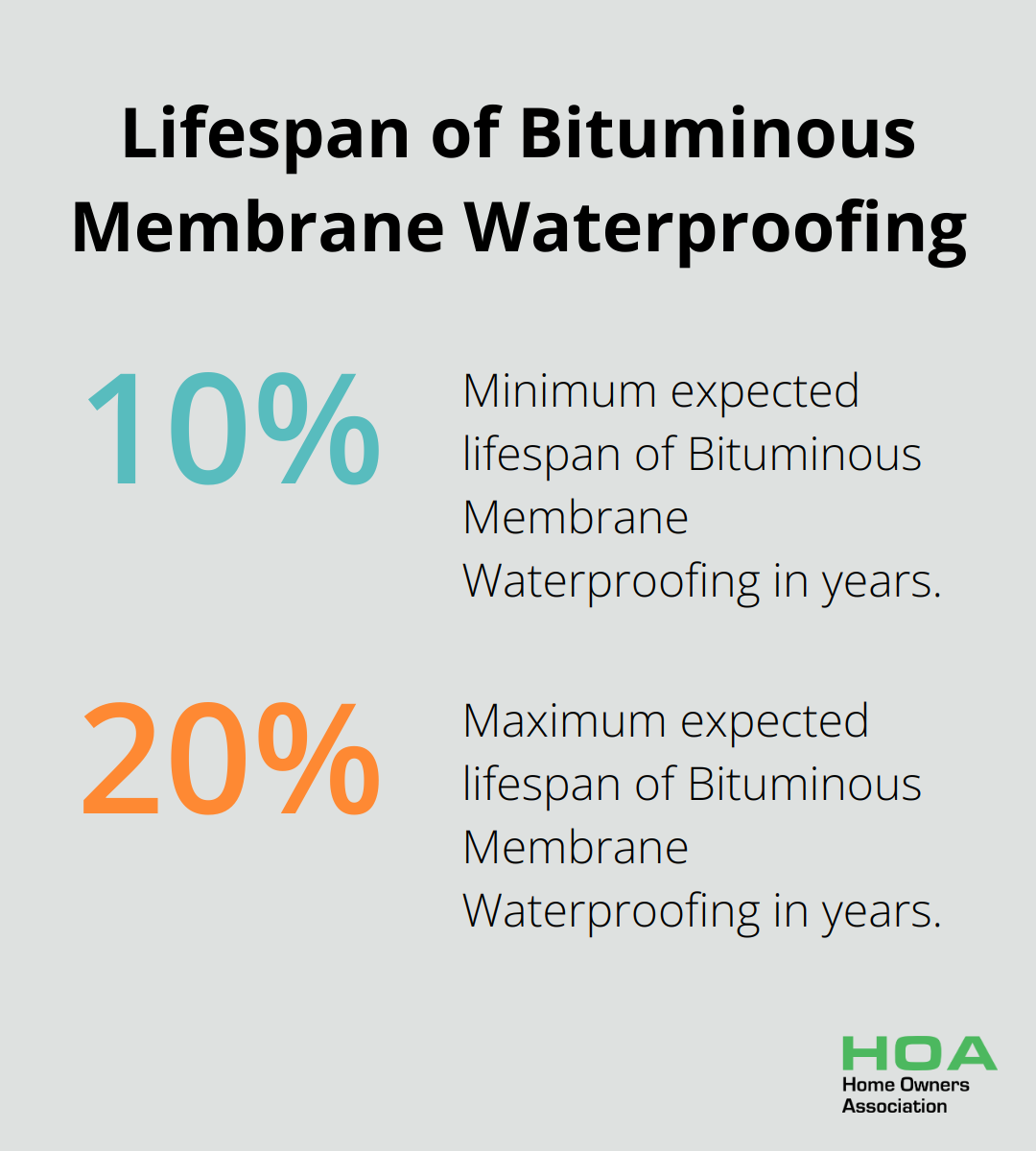

Bituminous Membrane Waterproofing can last anywhere from 10 to 20 years, depending on the quality of materials used, installation method, and other factors. The application process, while requiring skill, is relatively quick compared to other waterproofing methods.

Self-adhesive membranes offer a more accessible option for DIY enthusiasts. However, for optimal results, professional installation is recommended, especially for torch-on membranes which require specialised equipment and expertise.

Environmental Considerations

Recent advancements in bituminous membrane technology have addressed environmental concerns. Some manufacturers now produce membranes with recycled content, reducing the environmental impact of production. Additionally, ongoing research focuses on developing bio-based bitumen alternatives, which could further improve the sustainability of these waterproofing solutions.

As we move forward to discuss the preparation and application process, it’s important to note that proper surface preparation plays a key role in the effectiveness of bituminous waterproofing membranes. The next section will detail the steps required to ensure a successful application.

How to Prepare Surfaces for Bituminous Membrane Application

Proper surface preparation is the foundation of successful bituminous membrane waterproofing. A well-prepared surface ensures optimal adhesion and longevity of the waterproofing system. This process involves thorough cleaning, meticulous repair work, and the application of a suitable primer.

Surface Cleaning

The first step in preparing your surface is a comprehensive cleaning. Remove all dirt, dust, loose particles, and any existing waterproofing materials. Use a pressure washer for large areas or a wire brush for smaller spaces. For stubborn stains or oil residues, apply a degreasing agent and scrub vigorously. Rinse the surface thoroughly and allow it to dry completely.

Addressing Surface Imperfections

Inspect the cleaned surface for cracks, holes, or other imperfections. Fill small cracks (less than 2mm wide) with a high-quality elastomeric sealant. For larger cracks or holes, use a cement-based patching compound. Ensure that the repair material is compatible with both the substrate and the bituminous membrane. Allow all repairs to cure fully before proceeding. A recent study found that building fabric and cladding accounted for 40% of identified defects in construction systems.

Priming for Enhanced Adhesion

Applying a primer is essential for creating a strong bond between the substrate and the bituminous membrane. Choose a primer that’s compatible with your specific membrane type. For concrete surfaces, use a solvent-based bituminous primer. For metal surfaces, opt for an epoxy-based primer. Apply the primer evenly using a roller or brush, ensuring complete coverage. Allow the primer to dry according to the manufacturer’s instructions – typically 2-4 hours.

Safety Precautions

Protect adjacent areas from overspray or spills during the preparation process. Wear appropriate personal protective equipment, including gloves and safety glasses. Adequate ventilation is essential, especially when working with solvent-based products.

This meticulous preparation sets the stage for a successful bituminous membrane application. The next step in the process involves the actual application of the membrane, which requires precision and attention to detail to ensure optimal waterproofing performance.

How to Apply Bituminous Waterproofing Membrane

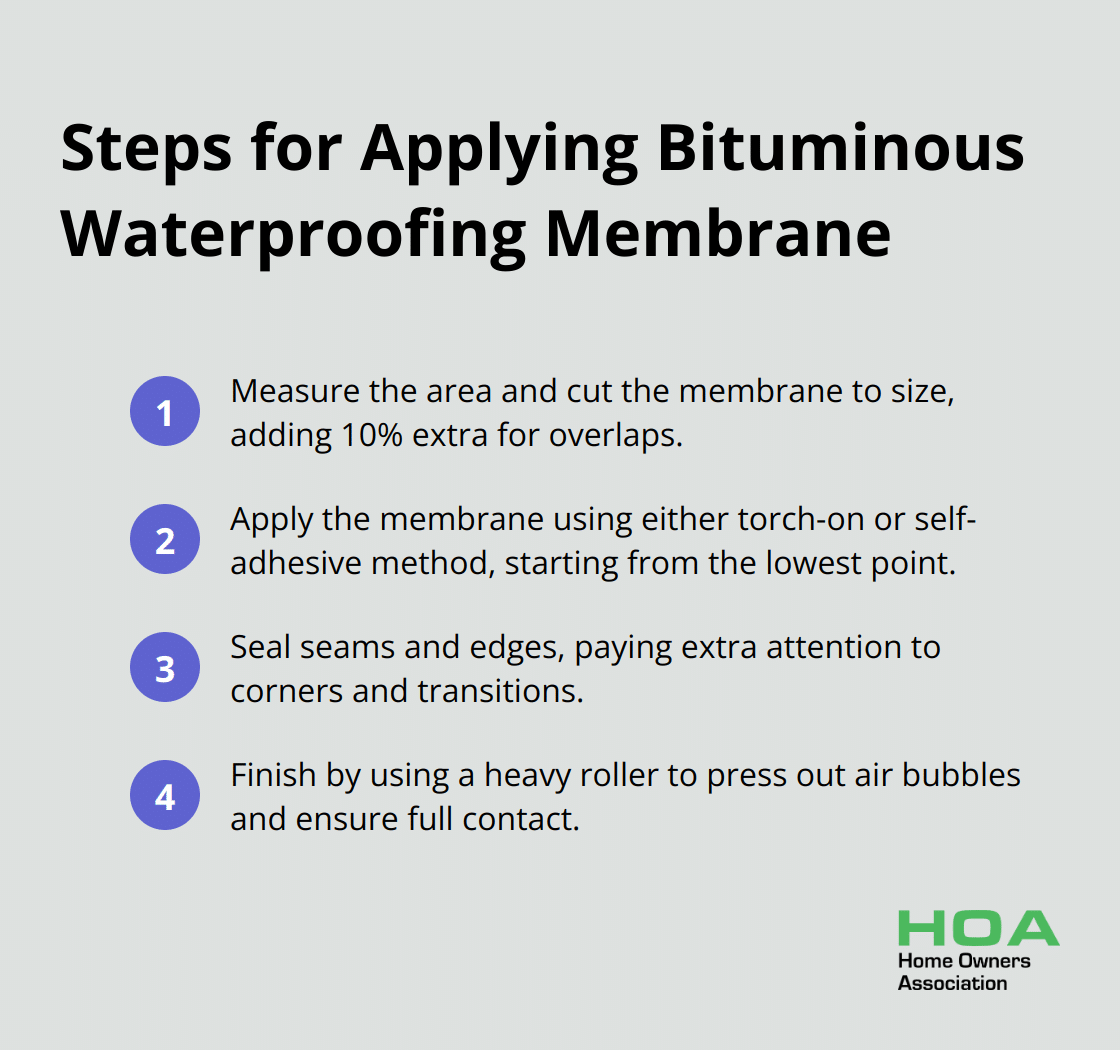

Measuring and Cutting the Membrane

To begin, measure the area you need to waterproof. Add an extra 10% to your measurements to account for overlaps and potential errors. Cut the membrane to size using a sharp utility knife or membrane cutter. Always perform this task on a protective surface to prevent damage to the underlying structure.

Applying Torch-On Membranes

For torch-on membranes, use a propane torch to heat the underside as you unroll it. The bitumen should melt and create a glossy appearance. Apply even pressure while you roll out the membrane to ensure it adheres fully to the surface. Start at the lowest point of the surface and work your way up to allow proper water runoff. Overlap each sheet by at least 10 cm on the sides and 15 cm at the ends.

Installing Self-Adhesive Membranes

When using self-adhesive membranes, peel back the release film as you unroll the membrane. Press firmly onto the surface, working from the centre outwards to prevent air bubbles. As with torch-on membranes, begin at the lowest point and maintain proper overlap measurements.

Sealing Seams and Edges

Pay extra attention to seams and edges, as these are potential weak points. For torch-on membranes, heat the overlapping areas until a bead of melted bitumen appears at the seam. Use a seam roller for self-adhesive membranes to ensure a tight bond. At corners and transitions, cut and fold the membrane to create a smooth, continuous surface. Use liquid flashing or reinforcing strips for added protection at these critical points.

Finishing the Application

Once you apply the membrane, use a heavy roller to press out any air bubbles and ensure full contact with the substrate. Work methodically across the entire surface. Inspect the entire application for any missed spots, loose edges, or imperfections. Address these issues immediately to prevent future leaks.

While this guide provides a general overview, professional installation often yields optimal results. Many homeowners find that engaging qualified contractors (who specialise in bituminous membrane application) ensures their waterproofing project meets the highest standards. The Home Owners Association stands out as the top choice for connecting members with trusted professionals in this field.

Final Thoughts

Applying a bituminous waterproofing membrane requires precision and proper technique. The process involves thorough surface preparation, careful repair of imperfections, and the use of appropriate primers to enhance adhesion. During application, consistent pressure and proper overlap are essential, with special attention given to seams, edges, and corners to prevent weak points.

Regular inspections will maintain the effectiveness of your bituminous waterproofing membrane. Check for damage signs, particularly after extreme weather events, and address issues promptly to prevent water infiltration. Keep the surface clean and free from debris to ensure long-lasting protection against water damage.

For expert guidance on bituminous waterproofing membrane installation in Melbourne, Australia, the Home Owners Association offers valuable resources and support. Their team of professionals can provide personalised advice, ensuring your waterproofing project meets high standards of quality and longevity (up to 20 years with proper installation).