At Home Owners Association, we understand the importance of effective waterproofing for protecting your property.

Sikagard waterproofing products offer a reliable solution to keep moisture at bay and preserve the integrity of your home’s structure.

In this guide, we’ll walk you through the process of using Sikagard for optimal results, from surface preparation to application techniques.

What Is Sikagard?

The Science Behind Sikagard

Sikagard represents a cutting-edge waterproofing solution that has transformed building protection against water damage. This innovative product line, created by Sika (a global leader in construction chemicals), offers a range of coatings that safeguard concrete and other building materials from moisture intrusion.

Sikagard uses advanced polymer technology to create a protective barrier that repels water while allowing the substrate to breathe. This unique feature distinguishes it from traditional waterproofing methods. For example, Sikagard-550 W Elastic (one of the most popular products in the line) can bridge cracks even at low temperatures (-20°C). This exceptional flexibility ensures long-lasting protection against water ingress, even in harsh climatic conditions.

Types of Sikagard Products

Sikagard offers a diverse range of products to address various waterproofing needs:

- Sikagard-700 S: A silane/siloxane-based water repellent ideal for absorbent cementitious substrates. It provides excellent water repellency and improves the thermal insulation properties of treated surfaces.

- Sikagard-680 S Betoncolor: This solvent-based coating offers outstanding protection against atmospheric influences. It not only waterproofs but also provides a self-cleaning effect, which reduces maintenance costs over time.

Advantages of Sikagard Waterproofing

The benefits of using Sikagard for waterproofing are numerous and significant:

- High CO2 Diffusion Resistance: Sikagard dramatically reduces carbonation rates in concrete, protecting steel reinforcement from corrosion. According to Sika’s technical data, the Sikagard-550 W Elastic has high diffusion resistance against CO2, reducing the rate of carbonation.

- Exceptional Durability: Sikagard products (such as the Sikagard-680 S Betoncolour) can remain effective for years, withstanding harsh weather conditions and UV exposure. This longevity translates to significant cost savings over time, as the need for frequent reapplication is greatly reduced.

- Versatility: Sikagard products can be applied to a wide range of surfaces, including concrete, brickwork, and natural stone. This flexibility makes Sikagard an ideal choice for both new construction and renovation projects.

Application and Performance

Sikagard products are known for their ease of application and superior performance. They can be applied using various methods (brush, roller, or spray), depending on the specific product and surface requirements. The application process typically involves surface preparation, priming (if necessary), and the application of one or more coats of the Sikagard product.

The performance of Sikagard products has been extensively tested and validated. For instance, the Sikagard-550 W Elastic has very good resistance against weathering and aging. This level of performance ensures long-term protection for treated surfaces.

As we move forward, it’s important to understand how to prepare surfaces for Sikagard application to maximise its effectiveness. The next section will guide you through the essential steps of surface preparation, ensuring optimal results for your waterproofing project.

How to Prepare Surfaces for Sikagard

Thorough Cleaning and Repair

Surface preparation is essential for the success of any Sikagard application. Start by cleaning the surface thoroughly. Remove all dirt, dust, oil, grease, and loose particles. For concrete surfaces, use a high-pressure water jet to achieve the best results. This method not only cleans but also helps identify any hidden defects.

After cleaning, repair any cracks, spalls, or other damage. For small cracks (less than 0.3 mm), you can use Sikagard-550 W Elastic directly. Larger cracks or structural damage require appropriate Sika repair mortars before applying the waterproofing coating.

Surface Priming Techniques

Priming is vital for optimal adhesion and performance of Sikagard products. The choice of primer depends on the substrate and the specific Sikagard product you plan to use.

For highly absorbent surfaces, use Sikagard-552 W Aquaprimer. Apply it evenly with a brush or roller, ensuring full coverage without leaving any pores untreated. Allow the primer to dry completely before applying the main Sikagard coating.

Dense or smooth surfaces require Sikagard-551 S Elastic Primer. This primer enhances adhesion on challenging substrates.

Optimal Application Conditions

The environment plays a significant role in the effectiveness of Sikagard application. Ideal conditions include:

Temperature: Apply Sikagard products when the ambient and substrate temperatures range between +8°C and +35°C. Avoid application in direct sunlight or during hot weather to prevent rapid drying.

Humidity: Keep relative humidity below 80%. High humidity can interfere with proper curing and adhesion.

Wind: Calm conditions are best. Strong winds can cause uneven application and premature drying.

Monitor weather forecasts and plan your application accordingly. It’s important to protect freshly applied Sikagard from rain for at least 4 hours after application.

The time invested in proper surface preparation will pay off in the long-term performance and durability of your waterproofing project. Now that we’ve covered surface preparation, let’s move on to the step-by-step guide for applying Sikagard products.

How to Apply Sikagard Effectively

Mixing and Preparation

Start by stirring the Sikagard product thoroughly. For Sikagard-550 W Elastic, stir the coating to ensure uniformity using a slow speed (400-600 rpm) drill and 1/2″ jiffy style mixing paddle. To minimise colour variation, follow the manufacturer’s specific mixing instructions.

Application Techniques

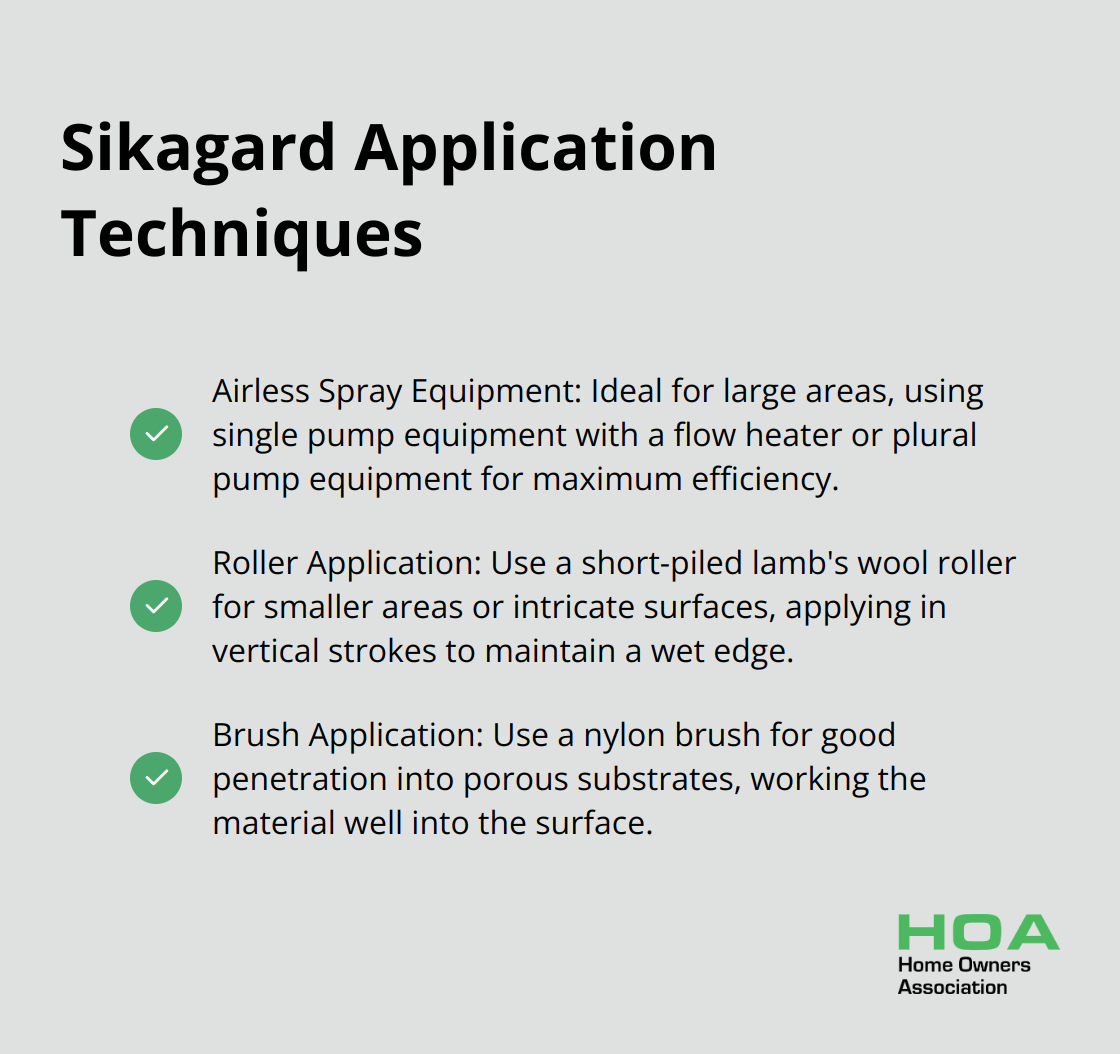

The application method depends on the surface and the specific Sikagard product. For large areas, use airless spray equipment for maximum efficiency. Sikagard®-831 is commonly applied by airless spray equipment, such as single pump equipment with a flow heater, or plural pump equipment.

For smaller areas or intricate surfaces, apply with a roller. Use a short-piled lamb’s wool roller and apply in vertical strokes. Maintain a wet edge to avoid lap marks.

When applying by brush, use a nylon brush and work the material well into the surface. This method ensures good penetration into porous substrates.

Proper Coverage

Apply Sikagard in two coats to ensure complete coverage. Maintain consistent thickness across the surface. Use a wet film gauge during application to check your progress. Under-application can compromise the waterproofing effectiveness, while over-application can lead to sagging or extended drying times.

Drying and Curing

Drying times vary depending on environmental conditions. During the curing period, protect the coated surface from rain, condensation, and water contact. Any exposure to moisture before the coating fully cures can lead to white discolouration or stickiness (which may impair the final appearance and performance).

These are general guidelines. Always refer to the specific product data sheet for the most accurate information tailored to your chosen Sikagard product.

Final Thoughts

Sikagard waterproofing products revolutionise building protection with their advanced polymer technology. These innovative solutions create a robust barrier against water intrusion while allowing structures to breathe, offering superior protection and longevity. The effectiveness of Sikagard stems from its innovative formulation and proper application, which includes thorough surface preparation, correct priming, and adherence to optimal application conditions.

The long-term benefits of using Sikagard for waterproofing are substantial. Its exceptional durability reduces the need for reapplications, resulting in significant cost savings over time. The high CO2 diffusion resistance protects concrete structures from carbonation, extending their lifespan (a feature particularly valuable in urban environments).

We at Home Owners Association understand the importance of protecting your investment in Melbourne’s diverse climate. Our members receive expert advice and access to quality products like Sikagard at trade prices. This combination of knowledge and savings ensures that your waterproofing projects are both effective and cost-efficient.