At Home Owners Association, we understand the critical role of electrical safety in maintaining a secure and functional home. Waterproofing electrical connectors is a vital skill for homeowners to protect their property from potential hazards.

Water damage to electrical systems can lead to costly repairs and dangerous situations. This guide will walk you through effective techniques for waterproofing electrical connectors, helping you safeguard your home’s electrical infrastructure.

Why Waterproof Electrical Connectors Matter

The Peril of Water and Electricity

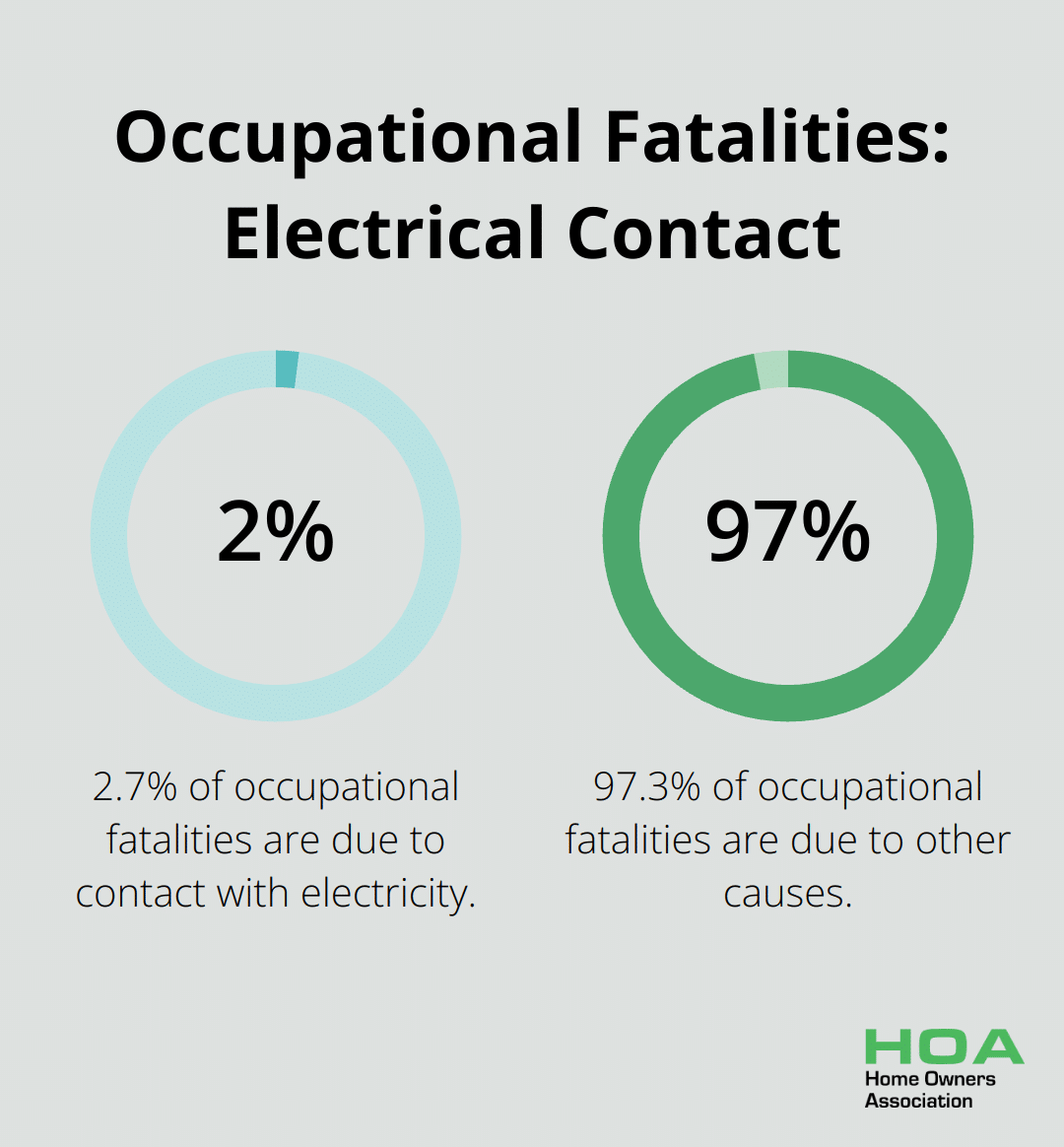

Water and electricity create a dangerous combination. This fact emphasizes the importance of waterproofing electrical connectors in various settings. Water intrusion into electrical connections can trigger short circuits, corrosion, and electrical fires. A total of 70,692 occupational fatalities occurred from all causes, with 1,940 of these due to contact with electricity, underscoring the urgent need for proper waterproofing measures.

Financial Consequences of Poor Waterproofing

Inadequate waterproofing leads to significant financial losses. The Insurance Information Institute states that water damage and freezing account for nearly 24% of all homeowners insurance claims, with an average claim cost of $11,650. Many of these incidents involve electrical systems compromised by moisture (a costly oversight that proper waterproofing can prevent).

Critical Applications for Waterproof Connectors

Waterproof electrical connectors play a vital role in numerous applications. Outdoor lighting systems, pool and spa equipment, and basement electrical installations all require robust waterproofing. Even indoor areas prone to humidity or occasional water exposure (such as bathrooms and kitchens) benefit from waterproof connectors.

The Long-Term Advantages of Effective Waterproofing

Quality waterproofing for electrical connectors offers long-term benefits. It extends the life span of electrical systems, reduces maintenance costs, and enhances overall reliability. The National Electrical Manufacturers Association (NEMA) standards for enclosure types provide guidelines for different levels of protection against water ingress, helping homeowners select the right solutions for their specific needs.

Choosing the Right Waterproofing Solution

Selecting the appropriate waterproofing method depends on the specific application and environment. Factors to consider include the level of water exposure, frequency of maintenance, and the type of electrical connection. Professional advice can help ensure the most effective waterproofing solution for your particular situation.

As we move forward, we’ll explore the various types of waterproof electrical connectors available in the market, each designed to address specific waterproofing needs and challenges.

Waterproof Connector Types for Electrical Safety

At Home Owners Association, we prioritise the protection of electrical connections from moisture. The right waterproof connector selection prevents costly damage and ensures the longevity of electrical systems in Australian homes.

IP-Rated Connectors: Decoding the Numbers

IP-rated connectors offer a popular choice for waterproofing electrical connections. The IP (Ingress Protection) rating system uses two-digit numbers to indicate an item’s resistance to various types of unwanted intrusion. An IP67 rating, for example, signifies that the connector is dust-tight and can withstand immersion in water up to 1 metre deep for 30 minutes.

For outdoor applications in Australia’s diverse climate, we recommend connectors with a minimum rating of IP65 (which protects against water jets from any direction). However, areas prone to flooding or near pool equipment require IP68 rated connectors that withstand continuous submersion.

Sealed Connectors: Robust Protection

Sealed connectors create a watertight barrier using gaskets, O-rings, or other sealing mechanisms. These prove particularly effective in marine environments or coastal areas where salt spray poses a concern. The Australian Standard AS/NZS 3000:2018 (Wiring Rules) requires that electrical installations in certain ‘special situations’ must comply with additional or varied installation requirements, making sealed connectors a suitable choice for compliance in many cases.

Bayonet-style connectors (a popular sealed connector type) provide a secure, twist-lock connection. Their reliability under vibration and moisture exposure makes them widely used in automotive and marine applications.

Hermetic Connectors: Extreme Condition Solutions

Hermetic connectors offer the highest level of protection against moisture and other contaminants. These connectors use glass-to-metal or ceramic-to-metal seals to create an airtight and watertight barrier. While more expensive, hermetic connectors prove essential for critical applications where failure is not an option.

In Australia, mining equipment and offshore installations often utilise hermetic connectors due to constant exposure to extreme conditions. The initial investment in hermetic connectors can lead to significant long-term savings by preventing system failures and reducing maintenance needs.

Overmoulded Connectors: Integrated Safeguarding

Overmoulded connectors feature a protective layer of plastic or rubber moulded directly over the connection point. This integrated approach provides excellent protection against moisture, dust, and physical stress. Overmoulded connectors work particularly well in high-vibration environments or where frequent handling occurs.

For DIY enthusiasts in Australia, pre-made overmoulded extension cords and power cables offer a simple solution for outdoor power needs. These products often come with warranties and withstand the harsh UV exposure common in the Australian climate.

When selecting waterproof connectors for your electrical projects, consider the specific environmental challenges of your location. Coastal areas may require more robust protection against salt corrosion, while inland regions might focus more on dust and occasional moisture exposure. The next section will guide you through the step-by-step process of effectively waterproofing these electrical connectors, ensuring optimal protection for your home’s electrical systems.

How to Waterproof Electrical Connectors

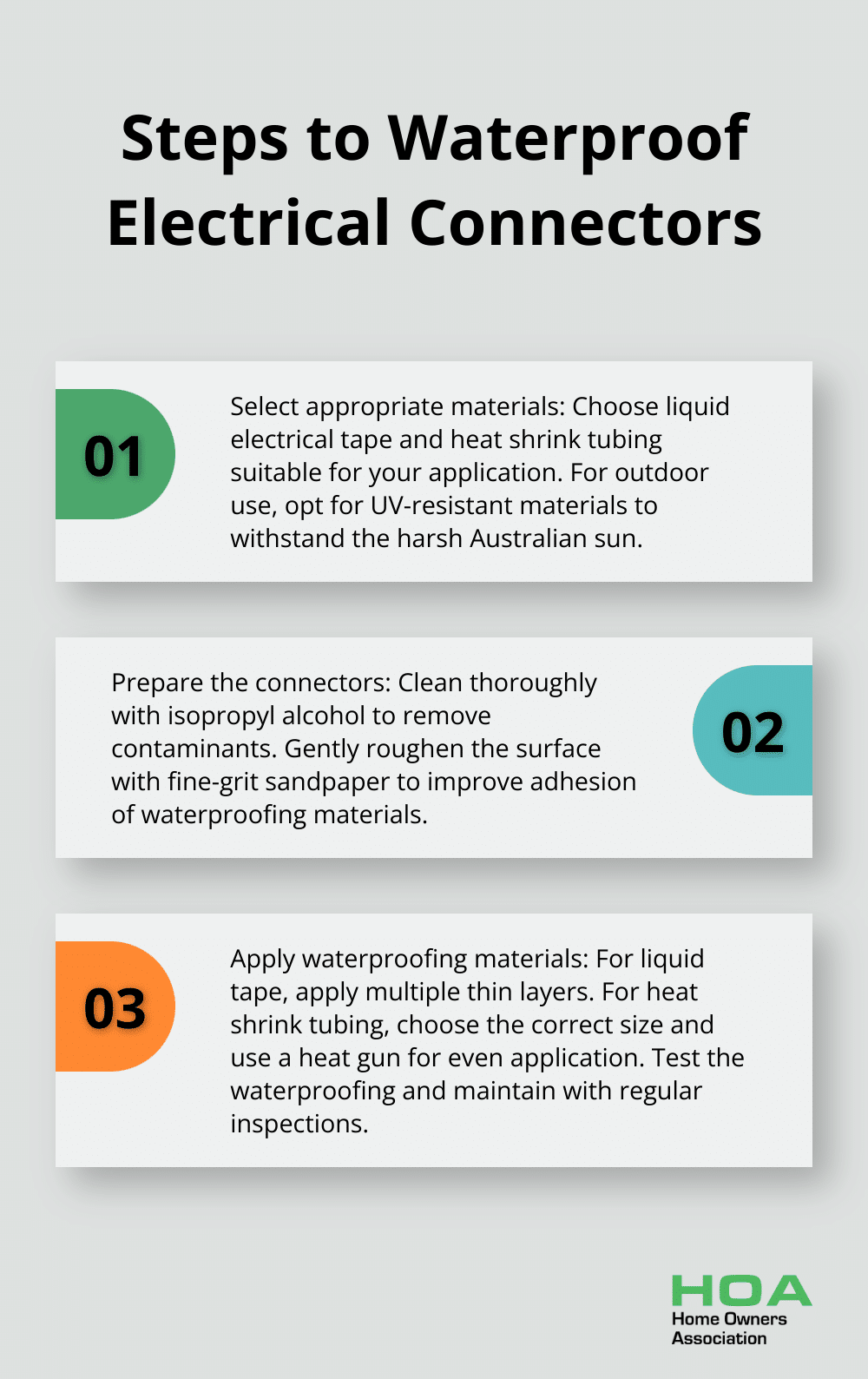

Select Appropriate Materials

The first step in waterproofing involves choosing the right materials. For most residential applications, we recommend a combination of liquid electrical tape and heat shrink tubing. Liquid electrical tape creates a flexible, water-resistant barrier (particularly effective for irregular shapes). Heat shrink tubing, when applied correctly, forms a tight seal around connectors and wires.

For outdoor applications exposed to UV rays, select UV-resistant materials. The Australian sun can damage standard plastics, causing them to break down over time. UV-resistant options may cost more initially, but they’ll prove more cost-effective in the long run due to their durability.

Prepare the Connectors

Before applying any waterproofing materials, clean the connectors thoroughly. Use isopropyl alcohol to remove dirt, grease, or moisture. This step is essential – even small amounts of contamination can prevent proper adhesion of waterproofing materials.

After cleaning, roughen the connector’s surface slightly with fine-grit sandpaper. This creates a better surface for the waterproofing materials to adhere to. Exercise caution to avoid damaging the connector during this process.

Apply Waterproofing Materials

When using liquid electrical tape, apply multiple thin layers instead of one thick coat. This method reduces the risk of bubbles or gaps in the waterproof seal. Allow each layer to dry completely before applying the next (typically about 10 minutes between coats).

For heat shrink tubing, choose the right-sized tubing with the correct shrink ratio. It should comfortably cover the wire or components before it has been shrunk. Position the tubing to overlap both the connector and a portion of the insulated wire. Use a heat gun to shrink the tubing, moving the heat source constantly to ensure even application and prevent burning.

Test the Waterproofing

After waterproofing, test the effectiveness of your seal. A simple method involves using a multimeter to check for continuity before and after submerging the connector in water (with the power off). If there’s any change in the reading, your waterproofing needs improvement.

For a more thorough test, some professionals use a vacuum test. This involves creating a vacuum around the connector and checking for any loss of pressure, which would indicate a leak in your waterproofing.

Maintain Regular Inspections

Waterproofing is not a one-time task. Regular inspections and maintenance are necessary to ensure continued protection. We recommend checking your waterproofed connections at least annually, or more frequently in harsh environments.

These steps will significantly reduce the risk of water damage to your electrical systems. This not only protects your home but can also lead to substantial savings on potential repairs. If you’re unsure about any step in the process, consult with a professional electrician for guidance.

Final Thoughts

Waterproofing electrical connectors protects your property and ensures safety. The right choice of connectors (IP-rated, sealed, hermetic, or overmoulded) depends on your specific needs. Proper preparation and careful application of waterproofing materials will provide long-lasting protection for your electrical systems.

Regular maintenance and inspection of waterproofed connections maintain their effectiveness over time. We recommend you check your waterproofed electrical connectors at least annually, or more frequently in harsh environments. Consider factors such as UV exposure, temperature fluctuations, and physical stress when selecting materials for your waterproof connections.

At Home Owners Association, we help Melbourne homeowners protect their investments and ensure the safety of their electrical systems. Our members receive expert advice, access to trade pricing, and resources to support their home improvement projects (including waterproofing electrical connectors). Prioritise this task to create a safer, more resilient home and potentially save on costly repairs.