Choosing the right bitumen waterproofing membrane is a critical decision for any construction or renovation project. At Home Owners Association, we understand the importance of protecting your property from water damage and structural issues.

This guide will help you navigate the complex world of bitumen membranes, exploring their types, key features, and factors to consider during selection. We’ll provide practical insights to ensure you make an informed choice for your specific needs.

Understanding Bitumen Waterproofing Membranes

Definition and Purpose

Bitumen waterproofing prevents water penetration into a site and protects against moisture’s destructive action on various surfaces. These membranes consist of a bitumen-based compound reinforced with polyester or fibreglass, creating a durable and flexible barrier against moisture.

Types of Bitumen Membranes

Two primary types of bitumen membranes exist: Atactic Polypropylene (APP) and Styrene Butadiene Styrene (SBS).

APP membranes perform better in high temperatures, maintaining their shape and integrity, while SBS membranes offer superior flexibility in colder environments.

Manufacturing Process and Components

The production of bitumen waterproofing membranes involves a complex process:

- Selection of high-quality bitumen

- Modification with polymers to enhance properties

- APP membranes: Addition of polypropylene for heat resistance

- SBS membranes: Incorporation of rubber-like polymers for improved elasticity

- Application to a reinforcement layer (polyester or fibreglass)

- Polyester: Provides excellent tensile strength and puncture resistance

- Fibreglass: Offers dimensional stability

- Some high-performance membranes use a combination of both materials

Performance Considerations

When selecting a bitumen membrane, consider the specific requirements of your project:

- Climate: For a roof in Brisbane (where temperatures soar), an APP membrane might be the best choice. For a building in Hobart (with harsh winters), an SBS membrane could provide better protection.

- Thickness: The thickness of the membrane plays a significant role in its performance. Thicker membranes generally offer better durability and longevity. Industry standards typically recommend membranes between 3mm to 5mm thick for most applications.

Application Methods

Bitumen waterproofing membranes can be applied using various techniques:

- Torch-on application: The membrane is heated with a torch to melt the bitumen and adhere it to the surface.

- Self-adhesive application: These membranes come with a pre-applied adhesive layer, making installation quicker and easier.

- Mechanical fixation: The membrane is secured using fasteners, particularly useful for certain roof types or in high-wind areas.

The choice of application method depends on factors such as the substrate type, climate conditions, and project requirements. Professional installation is always recommended to ensure optimal performance and longevity of the waterproofing system.

As we move forward, let’s explore the key factors you should consider when choosing a bitumen membrane for your specific project needs.

Factors Influencing Bitumen Membrane Selection

Selecting the right bitumen waterproofing membrane requires careful consideration of several key factors. Let’s explore the critical elements you need to consider for your waterproofing project.

Climate and Weather Conditions

The local climate significantly impacts membrane selection. In areas with extreme temperature fluctuations (like Melbourne, where temperatures can range from near-freezing to over 40°C), you need a membrane with excellent thermal stability. SBS membranes excel in colder climates due to their flexibility, while APP membranes perform better in hotter regions.

For coastal areas exposed to salt spray (such as Sydney or Perth), choose membranes with enhanced chemical resistance. The Australian Building Codes Board recommends selecting membranes that can withstand local weather patterns and potential climate change impacts.

Substrate Compatibility

The surface you’re waterproofing greatly influences membrane choice. Concrete substrates, common in commercial buildings, require membranes with strong adhesive properties. For metal roofs, often found in industrial settings, look for membranes that can accommodate thermal expansion and contraction.

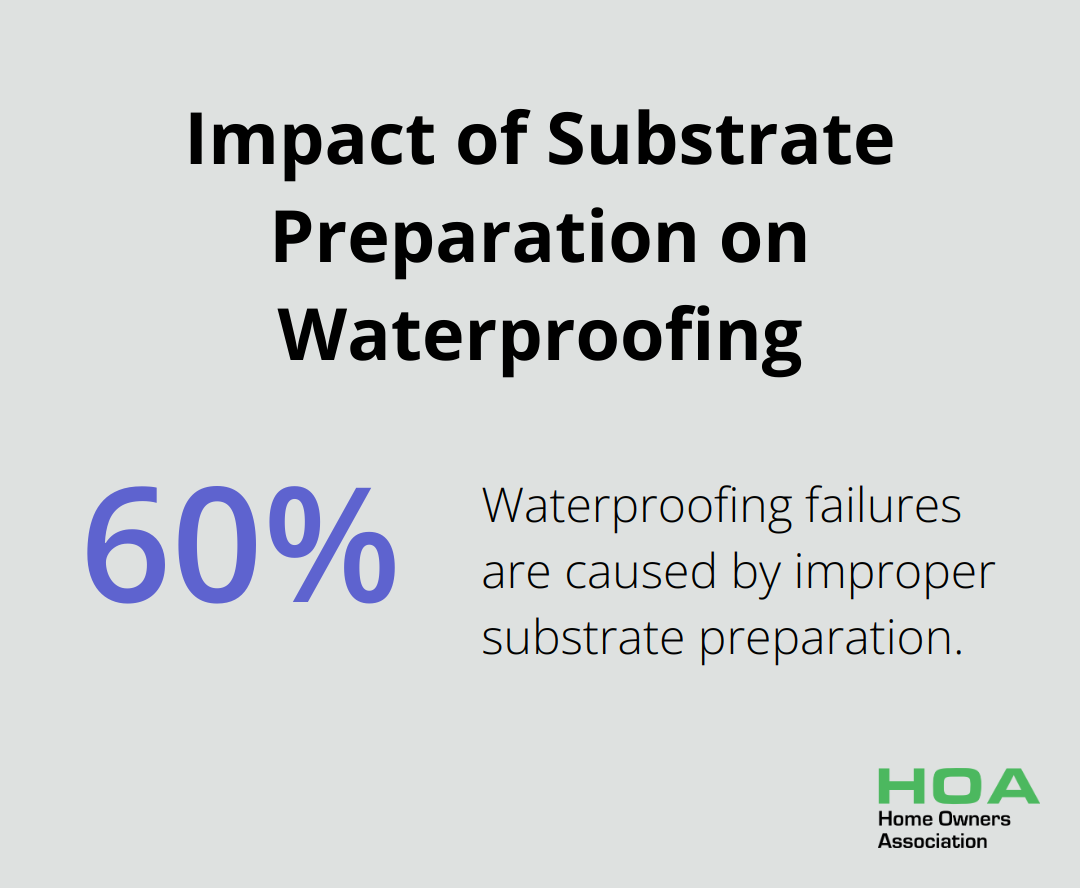

A study found that improper substrate preparation accounts for 60% of waterproofing failures. Always ensure the substrate is clean, dry, and properly primed before application.

Application Method Considerations

The choice between torch-on, self-adhesive, or mechanically fixed membranes depends on various factors:

Torch-on membranes offer excellent bonding but require skilled application. They’re ideal for large, flat surfaces.

Self-adhesive options are safer and easier to install, making them suitable for DIY projects or areas where open flames are prohibited.

Mechanically fixed membranes work well on substrates that are difficult to adhere to or in high-wind areas. The Australian Wind Loading Standard AS/NZS 1170.2 provides guidelines for wind resistance requirements.

Membrane Thickness and Reinforcement

Thicker membranes (typically 4mm or more) offer better durability and puncture resistance, especially for high-traffic areas or green roofs.

Reinforcement type affects membrane performance. Polyester reinforcement provides excellent tensile strength and puncture resistance, while fibreglass offers dimensional stability. Some high-performance membranes combine both materials for optimal results.

UV Resistance and Surface Finish

For exposed applications, UV resistance is essential. Look for membranes with mineral granule or aluminium foil surfaces that reflect UV rays. These finishes not only protect the membrane but can also contribute to energy efficiency by reducing heat absorption.

The Building Code of Australia specifies reflectivity requirements for roofing materials in certain climate zones. Choosing a highly reflective surface finish can help meet these standards and reduce cooling costs.

Now that we’ve covered the key factors affecting bitumen membrane selection, let’s explore the top features you should look for in quality bitumen membranes to ensure optimal performance and longevity.

What Makes a Quality Bitumen Membrane?

Flexibility and Durability

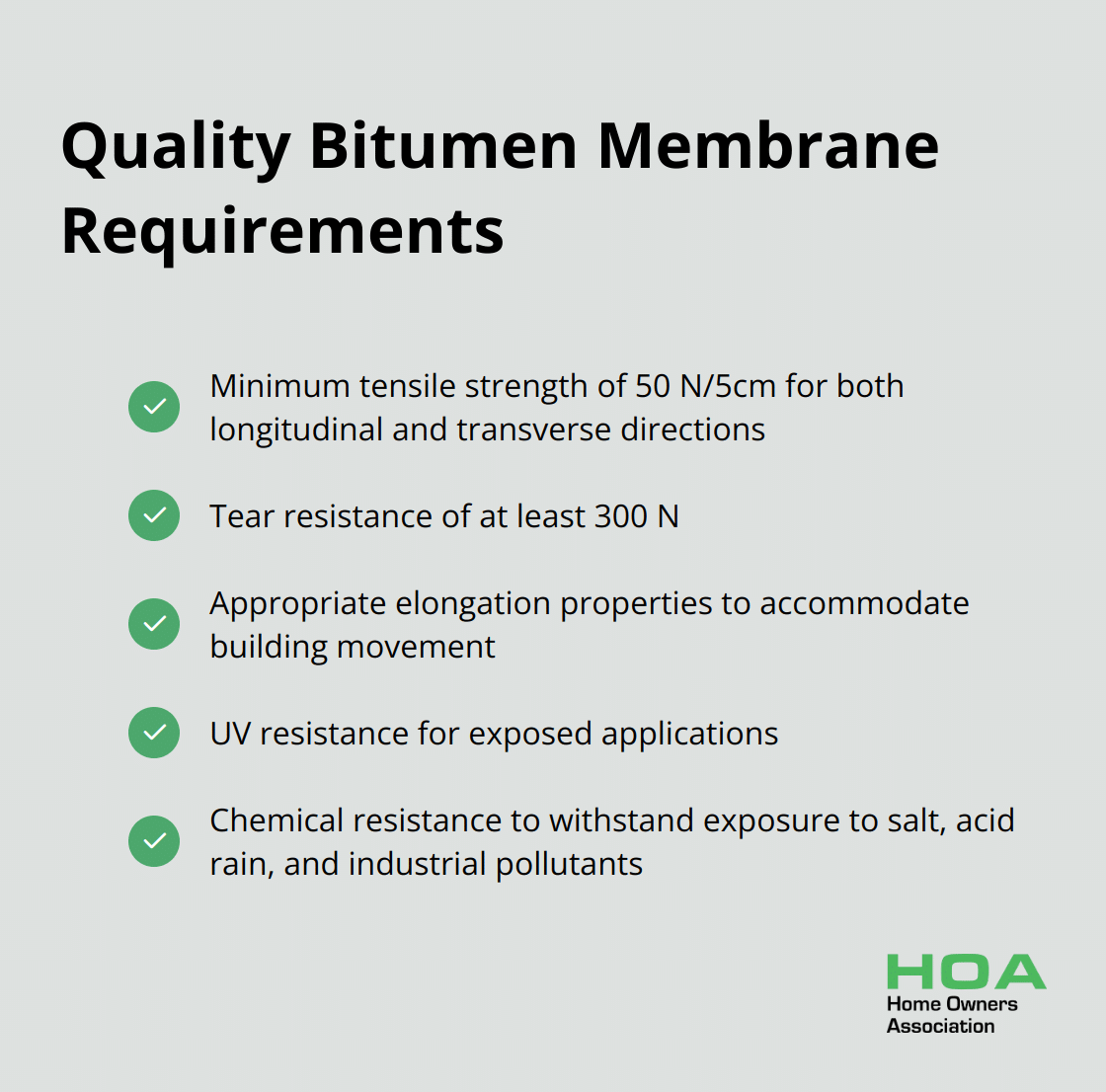

The ability of a membrane to stretch and recover is essential. Select membranes with appropriate elongation properties. This flexibility allows the membrane to accommodate building movement and temperature changes without cracking.

Tensile strength plays a vital role. A high-quality membrane should have a minimum tensile strength of 50 N/5cm for both longitudinal and transverse directions. This ensures the membrane can withstand the stresses of installation and long-term use.

Tear resistance protects against damage. Choose membranes with a tear resistance of at least 300 N. This safeguards against damage from foot traffic or falling objects during and after installation.

Chemical and Environmental Resistance

In coastal areas or industrial zones, chemical resistance becomes paramount. Select membranes that can withstand exposure to salt, acid rain, and industrial pollutants. Products that have undergone accelerated weathering tests (simulating years of exposure in harsh conditions) offer superior protection.

UV resistance is essential for exposed applications. Membranes with mineral granule or aluminium foil surfaces offer superior protection against solar radiation. These surfaces can reflect up to 80% of UV rays, significantly extending the membrane’s lifespan.

Fire Safety

Fire resistance is a critical consideration (especially in bushfire-prone areas). The Australian Standard AS/NZS 1530.3 sets the benchmark for fire performance. This standard includes measures for spread of flame and fire resistance for building elements.

Warranty and Manufacturer Credibility

A comprehensive warranty demonstrates a manufacturer’s confidence in their product. Leading manufacturers offer warranties ranging from 10 to 20 years. However, the length of the warranty isn’t everything. Pay attention to what’s covered and any exclusions.

Research the manufacturer’s reputation in the industry. Look for companies with a track record of innovation and quality control. The Australian Institute of Waterproofing (AIW) provides valuable resources for identifying reputable manufacturers and installers.

Proper installation remains key to warranty validity. Even the best membrane can fail if not installed correctly. Work with certified installers who are familiar with the specific product you’ve chosen.

Performance in Australian Conditions

Australia’s diverse climate demands membranes that can perform in extreme conditions. Try products that have been tested and proven effective in our unique environment. The CSIRO has conducted extensive research on membrane performance in Australian conditions, providing valuable insights for selection.

In tropical North Queensland (where annual rainfall can exceed 2000mm), membranes with exceptional water resistance and fungal growth inhibitors are essential. In contrast, the arid conditions of central Australia require membranes with superior heat resistance and minimal thermal expansion.

Final Thoughts

The selection of a bitumen waterproofing membrane significantly impacts your property’s long-term integrity. Climate, substrate compatibility, and application methods are key factors to consider when choosing the right membrane for your specific needs. Professional installation ensures the effectiveness of your chosen membrane, as even high-quality products can fail if not applied correctly.

Regular maintenance and inspections will identify potential issues early, extending the life of your waterproofing system. A well-chosen and properly installed bitumen waterproofing membrane protects your property from water damage, reduces maintenance costs, and enhances your building’s overall value. Investing time and resources in selecting the best membrane pays off in the long run.

Home Owners Association offers expert advice, access to trade pricing, and personalised guidance to help you navigate home improvement projects (including waterproofing solutions). Our team in Melbourne, Australia, supports you in making informed decisions about your property. With our assistance, you can confidently select and implement the best waterproofing solutions for your property.