At Home Owners Association, we understand the importance of effective waterproofing for protecting your property.

Sikalastic waterproofing systems offer a reliable solution for home owners looking to safeguard their buildings against water damage.

In this guide, we’ll walk you through the process of using Sikalastic products, from preparation to application, ensuring you have the knowledge to tackle your waterproofing project with confidence.

What is Sikalastic?

Sikalastic represents a groundbreaking waterproofing system that transforms how we shield buildings from water damage. This innovative product line, developed by Sika (a global leader in construction chemicals), offers solutions for various waterproofing needs.

The Science Behind Sikalastic

The effectiveness of Sikalastic stems from its unique chemical composition. The product utilises advanced polyurethane technology, which allows it to maintain flexibility even in extreme temperatures. This flexibility enables the membrane to move with the building, preventing cracks and maintaining its waterproof integrity over time.

Types of Sikalastic Products

Sika offers a range of Sikalastic products, each designed for specific applications:

- Sikalastic-560: A cold-applied, one-component waterborne liquid ideal for roof waterproofing. It boasts high elasticity and UV resistance, making it perfect for exposed areas.

- Sikalastic-1K: A fibre-reinforced mortar that can be applied by brush, roller, or spray. This product excels in waterproofing basements, swimming pools, and other areas subject to high water pressure.

Advantages of Sikalastic Waterproofing

Sikalastic offers several key benefits:

- Easy Application: Unlike traditional sheet membranes, Sikalastic can be applied directly to complex geometries without seams or joints (often the weak points in waterproofing systems).

- Durability: Sikalastic membranes can provide protection when properly installed and maintained.

- Environmentally Friendly: Many Sikalastic products have low VOC emissions, contributing to better indoor air quality and meeting stringent environmental standards. (The Sikalastic-560, for example, is certified to meet LEED v2009 standards for low-emitting materials.)

Performance in Various Conditions

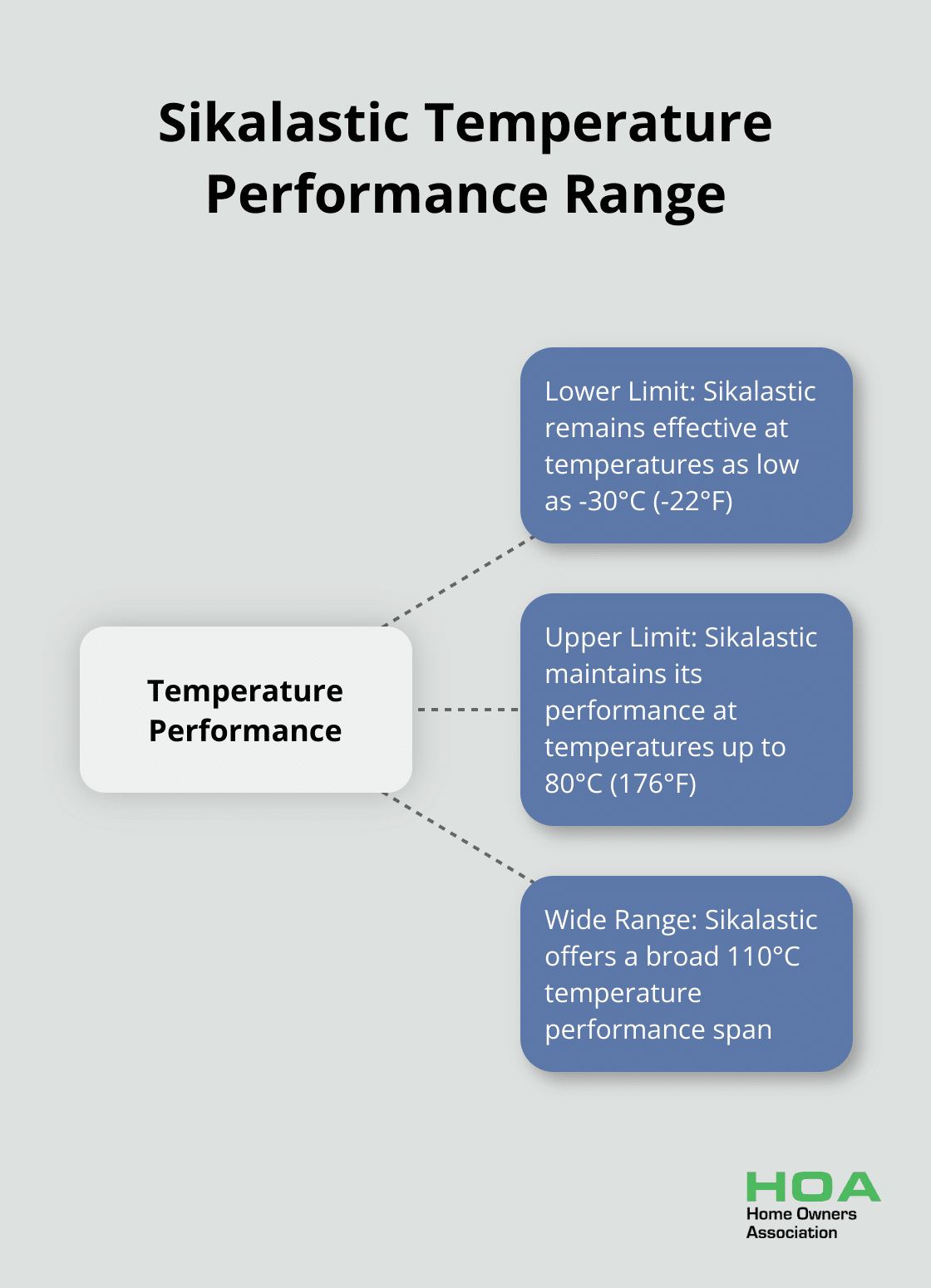

Sikalastic products demonstrate impressive performance across different environmental conditions:

- Temperature Resistance: Sikalastic maintains its effectiveness in temperatures ranging from -30°C to 80°C (-22°F to 176°F).

- UV Resistance: Many Sikalastic products (such as Sikalastic-560) offer excellent UV resistance, making them suitable for exposed applications.

- Chemical Resistance: Sikalastic membranes resist a wide range of chemicals, including mild acids, alkalis, and biological agents.

As we move forward to discuss the preparation process for Sikalastic application, it’s important to note that proper surface preparation plays a vital role in maximising the effectiveness of these advanced waterproofing systems.

How to Prepare for Sikalastic Application

Surface Preparation: The Foundation of Success

The first step in any Sikalastic application is meticulous surface preparation. Clean the area thoroughly to remove all dirt, dust, grease, and loose particles. For concrete surfaces, use a high-pressure washer to ensure a clean substrate. For metal surfaces, remove any rust or corrosion with a wire brush or sandblasting equipment.

Repair any cracks or damages in the substrate. Use a suitable Sika repair mortar to fill in cracks larger than 0.3mm on concrete surfaces. Address smaller cracks during the Sikalastic application process. For metal surfaces, treat corrosion spots with an appropriate rust converter before proceeding.

Allow the surface to dry completely after repairs. Sikalastic® Moisture Seal can be used as a primer over damp concrete and damp screeds prior to the application of various Sika® waterproofing membranes. Excess moisture can compromise the adhesion and performance of the waterproofing system.

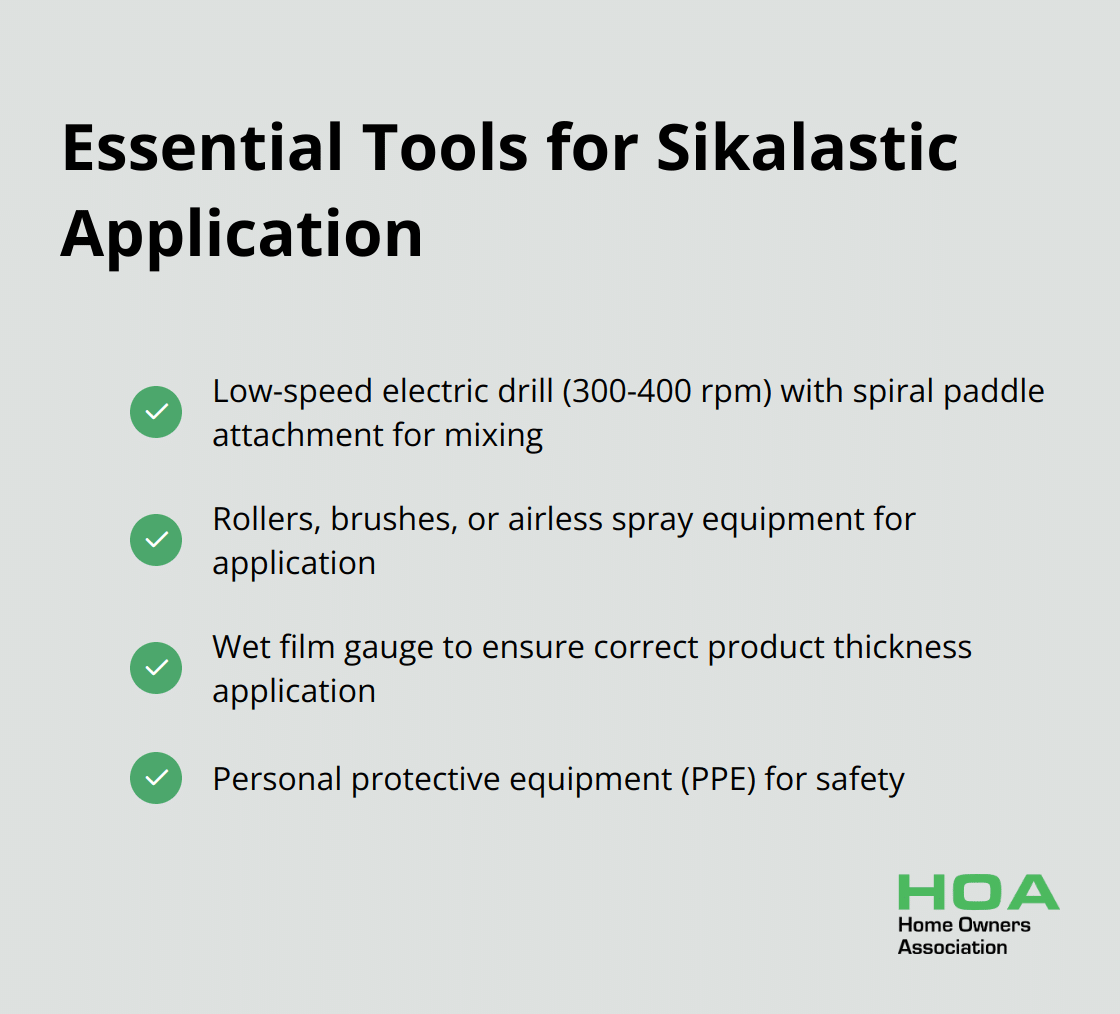

Essential Tools and Equipment

To apply Sikalastic effectively, you’ll need the right tools:

- For mixing: A low-speed electric drill (300-400 rpm) with a spiral paddle attachment.

- For application: Rollers, brushes, or airless spray equipment (depending on the specific Sikalastic product and project size). For Sikalastic-560, a short-piled roller works well for smaller areas, while airless spray equipment is more efficient for larger surfaces.

- For measurement: A wet film gauge to ensure correct product thickness application.

- For safety: Personal protective equipment (more details in the next section).

Safety First: Protective Gear and Precautions

Safety is paramount when working with construction chemicals. Always wear appropriate personal protective equipment (PPE) when applying Sikalastic products:

- Chemical-resistant gloves

- Safety goggles or a face shield

- Protective clothing that covers arms and legs

- A respirator mask (especially when working in poorly ventilated areas or using spray application methods)

Ensure proper ventilation in the work area. If working indoors, use fans to promote air circulation. Always read and follow the safety instructions provided in the product’s Material Safety Data Sheet (MSDS).

Environmental Considerations

Consider the environmental conditions before starting your Sikalastic application. The ideal temperature range for application is between 5°C and 35°C (41°F to 95°F). Avoid applying the product in direct sunlight or during extreme weather conditions (such as high winds or rain).

Check the weather forecast before starting your project. Plan your application for a time when you can expect at least 24 hours of dry weather after application (this allows the product to cure properly).

Now that you’ve prepared your surface, gathered your tools, and taken necessary safety precautions, you’re ready to move on to the actual application process. In the next section, we’ll provide a step-by-step guide on how to apply Sikalastic products for maximum effectiveness.

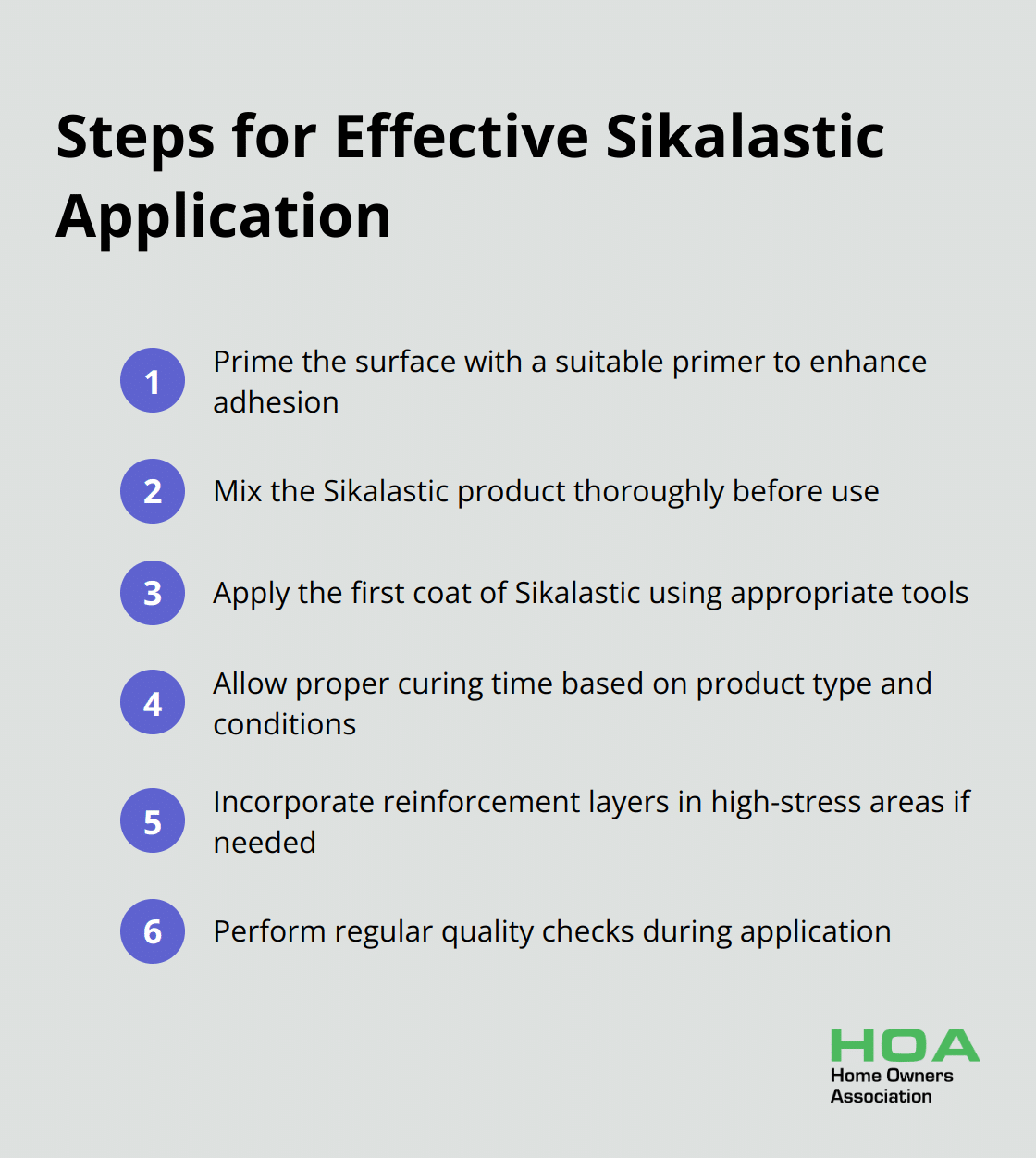

How to Apply Sikalastic for Maximum Effectiveness

Priming: Your First Defence

Start with the application of a suitable primer to enhance adhesion and seal porous surfaces. For concrete substrates, use Sika Concrete Primer or Sika Bonding Primer. On metal surfaces, choose Sikalastic Metal Primer. Apply the primer with a roller or brush, ensuring even coverage. Allow the primer to dry completely before proceeding (typically 2-4 hours, depending on ambient conditions).

Mixing and Application: Precision Matters

Mix the Sikalastic product thoroughly before use. For single-component products like Sikalastic-560, stir for at least one minute to ensure uniform consistency. For two-component products, mix Part A and Part B separately before combining them according to the manufacturer’s instructions.

Apply the first coat of Sikalastic using a roller, brush, or airless spray equipment. Work in one direction to ensure even coverage. The application rate varies depending on the specific product and surface conditions (typically ranging from 0.75 to 1.5 litres per square metre). Use a wet film gauge to check the thickness during application.

Curing: Allow Proper Time

Curing times vary based on product type, temperature, and humidity. Sikalastic-560 should be applied at an ambient air temperature between +8°C min. and +40°C max., with a relative air humidity of 80% max. During this time, protect the treated area from foot traffic and direct water contact. Adequate ventilation is essential for proper curing, especially in enclosed spaces.

Reinforcement: Add Strength to Layers

For areas subject to movement or high stress, incorporate reinforcement layers. Roof coatings may need partial reinforcement over areas of stress or predictable movement, such as joints, overlaps, and detailing. Apply a coat of Sikalastic, immediately embed Sika Reemat or Sika Flexitape, and then apply another layer of Sikalastic while the first is still wet. This technique is particularly effective for joints, corners, and areas around penetrations.

Quality Control: Ensure Proper Application

Perform regular checks during the application process to ensure consistent coverage and thickness. Use a wet film gauge to measure the thickness of the applied Sikalastic layer. Try to maintain the recommended thickness throughout the application area. Inspect the surface for any missed spots or thin areas, and address them immediately. This attention to detail will result in a more effective and long-lasting waterproofing system.

Final Thoughts

Sikalastic waterproofing systems provide a robust solution to protect your property from water damage. You will achieve optimal results if you follow the steps outlined in this guide for effective application of Sikalastic products. Regular inspections and prompt addressing of wear or damage will maintain the effectiveness of your waterproofing system.

Sikalastic excels as a reliable choice for waterproofing projects due to its versatility, easy application, and proven performance in various environments. Its seamless membrane formation and excellent adhesion properties make it ideal for both simple and complex waterproofing needs. The product’s ability to withstand diverse conditions (including temperatures from -30°C to 80°C) further solidifies its position as a top choice in the industry.

We at Home Owners Association understand the importance of protecting your investment in Melbourne, Australia. Our members receive expert advice, trade pricing, and discounts on construction materials, including waterproofing products. You will ensure your Sikalastic waterproofing project meets the highest standards of quality and effectiveness when you leverage our resources and guidance.