At Home Owners Association, we understand the importance of protecting your property from water damage. Cement waterproofing is a critical step in safeguarding your home’s foundation and structure.

This guide will walk you through the essential methods and techniques to effectively waterproof cement surfaces. We’ll cover everything from surface sealants to crystalline technology, ensuring you have the knowledge to keep your home dry and secure.

Why Waterproof Cement?

The Importance of Cement Waterproofing

Cement waterproofing protects structures from water damage, extends their lifespan, and maintains their integrity. This process can save homeowners thousands in repair costs.

Defining Cement Waterproofing

Cementitious waterproofing systems involve the use of cement-based materials mixed with polymers or additives to create a waterproof barrier. These materials prevent water from penetrating concrete structures, protecting the cement from deterioration and the steel reinforcements from corrosion.

The High Cost of Water Infiltration

Water infiltration in cement structures leads to numerous problems. In Australia’s harsh climate conditions, severe cases of concrete cancer (caused by water seepage) occur. This happens when water reaches steel reinforcements, causing them to rust and expand, which results in cracks and spalling in the concrete.

A study carried out by the CSIRO in 2008 found that the total cost of corrosion in steel structures is significant, allowing for comparison of lifecycle costs. This highlights the need for effective waterproofing.

Long-Term Advantages of Waterproofing

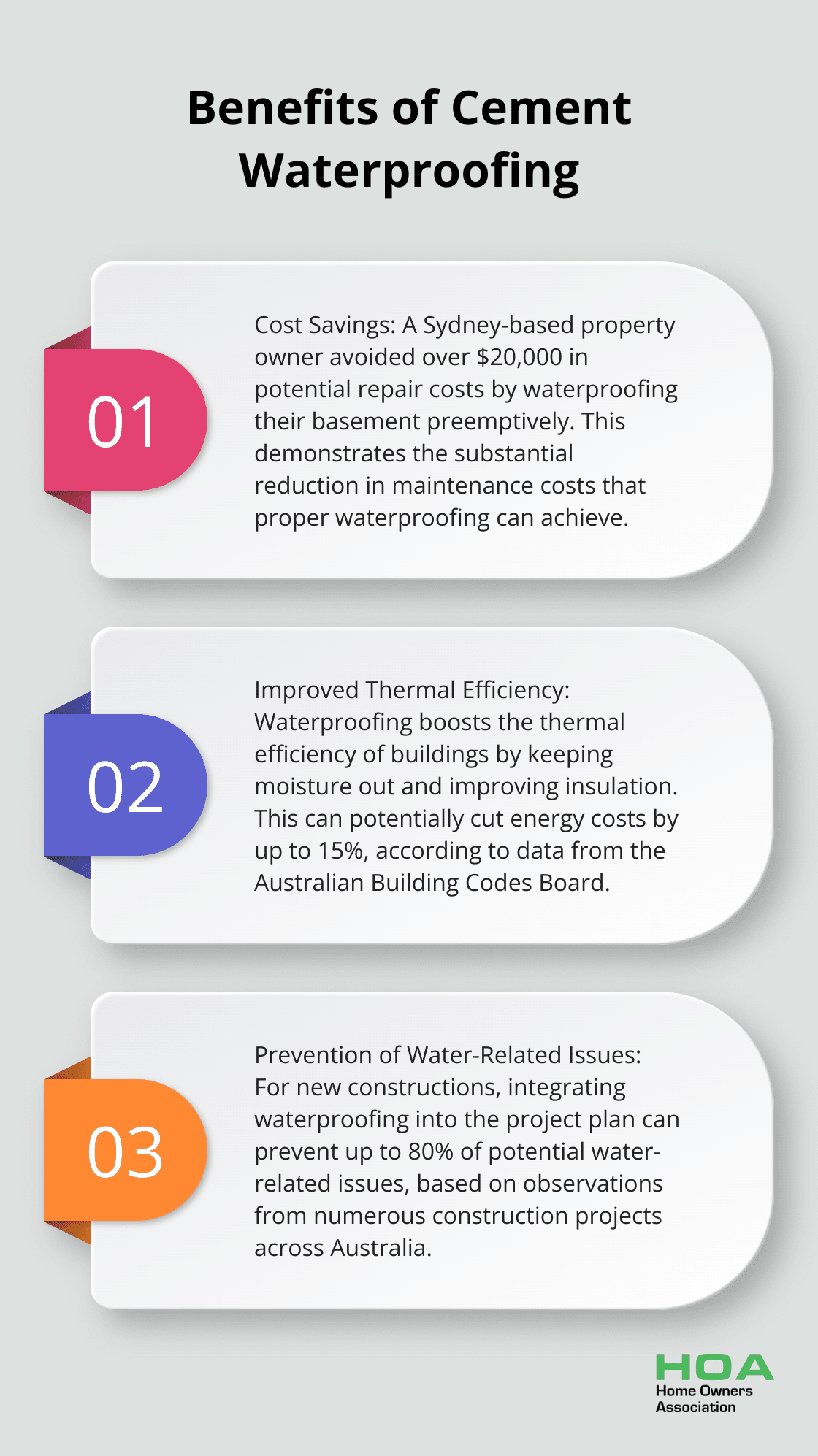

Proper cement waterproofing offers significant long-term benefits. It reduces maintenance costs substantially. For example, a Sydney-based property owner avoided over $20,000 in potential repair costs by waterproofing their basement preemptively.

Waterproofing also boosts the thermal efficiency of buildings. By keeping moisture out, it improves insulation, potentially cutting energy costs by up to 15% (according to data from the Australian Building Codes Board).

Optimal Timing for Waterproofing

The ideal time to waterproof cement is during the construction phase. However, existing structures can also benefit from waterproofing treatments. Property owners should assess their buildings annually for signs of water damage (such as efflorescence, mould growth, or dampness).

For new constructions, integrating waterproofing into the project plan is essential. This proactive approach can prevent up to 80% of potential water-related issues, based on observations from numerous construction projects across Australia.

As we move forward, let’s explore the various methods available for waterproofing concrete, each offering unique advantages for different situations and structures.

Effective Cement Waterproofing Techniques

At Home Owners Association, we’ve observed the impact of various waterproofing methods on cement structures. Let’s explore the most effective techniques that have yielded success for our members across Australia.

Surface-Applied Sealants and Coatings

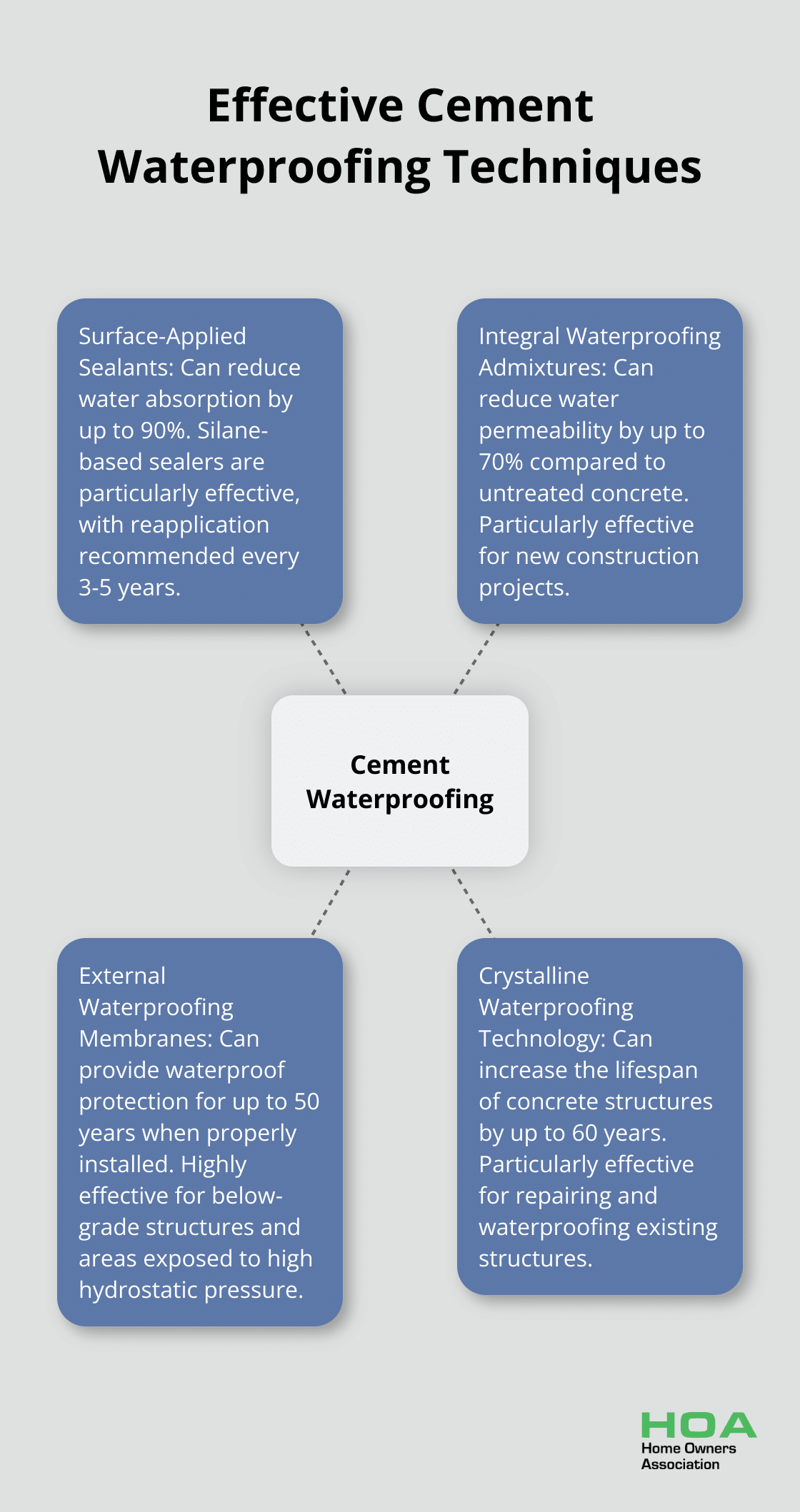

Penetrating sealers soak into the concrete, creating a chemical barrier against water infiltration. Silane-based sealers are particularly effective for this purpose.

The Australian Building Codes Board reports that properly applied sealants can reduce water absorption by up to 90%. However, their effectiveness depends on proper application and regular maintenance. We recommend that you reapply these sealants every 3-5 years for optimal protection.

A member in Brisbane reported a 75% reduction in basement dampness after applying a high-quality silane-siloxane sealer. This type of sealer penetrates the concrete and creates a hydrophobic barrier without changing the surface appearance.

Integral Waterproofing Admixtures

Manufacturers mix integral waterproofing admixtures directly into the cement during the batching process. This method provides comprehensive protection throughout the entire concrete structure.

The Concrete Institute of Australia found that integral waterproofing can reduce water permeability by up to 70% compared to untreated concrete. This method proves particularly effective for new construction projects.

A Sydney-based member used an integral crystalline waterproofing admixture in their foundation concrete. They reported no water ingress issues even after heavy rainfall (which previously caused flooding in their basement).

External Waterproofing Membranes

External waterproofing membranes are highly effective for below-grade structures and areas exposed to high hydrostatic pressure. Professionals apply these membranes to the exterior of cement structures, creating a physical barrier against water infiltration.

The Australian Waterproofing Industry Association reports that properly installed external membranes can provide waterproof protection for up to 50 years. However, the installation process is critical and requires experienced professionals.

A Melbourne property developer who used a high-grade polyurethane membrane on a multi-storey car park foundation saw a complete elimination of water seepage issues that had plagued the structure for years.

Crystalline Waterproofing Technology

Options to effectively waterproof concrete structures include a variety of integral & surface applied products and systems. Crystalline waterproofing technology is one such method that’s gaining popularity among our members.

Research from the University of New South Wales showed that crystalline waterproofing can increase the lifespan of concrete structures by up to 60 years. This technology is particularly effective for repairing and waterproofing existing structures.

A Gold Coast resort owner used crystalline waterproofing to treat their beachfront pool area. They reported a 95% reduction in maintenance costs related to water damage in the first year after application.

Now that we’ve covered the most effective waterproofing techniques, let’s move on to a step-by-step guide on how to apply these methods to your cement structures.

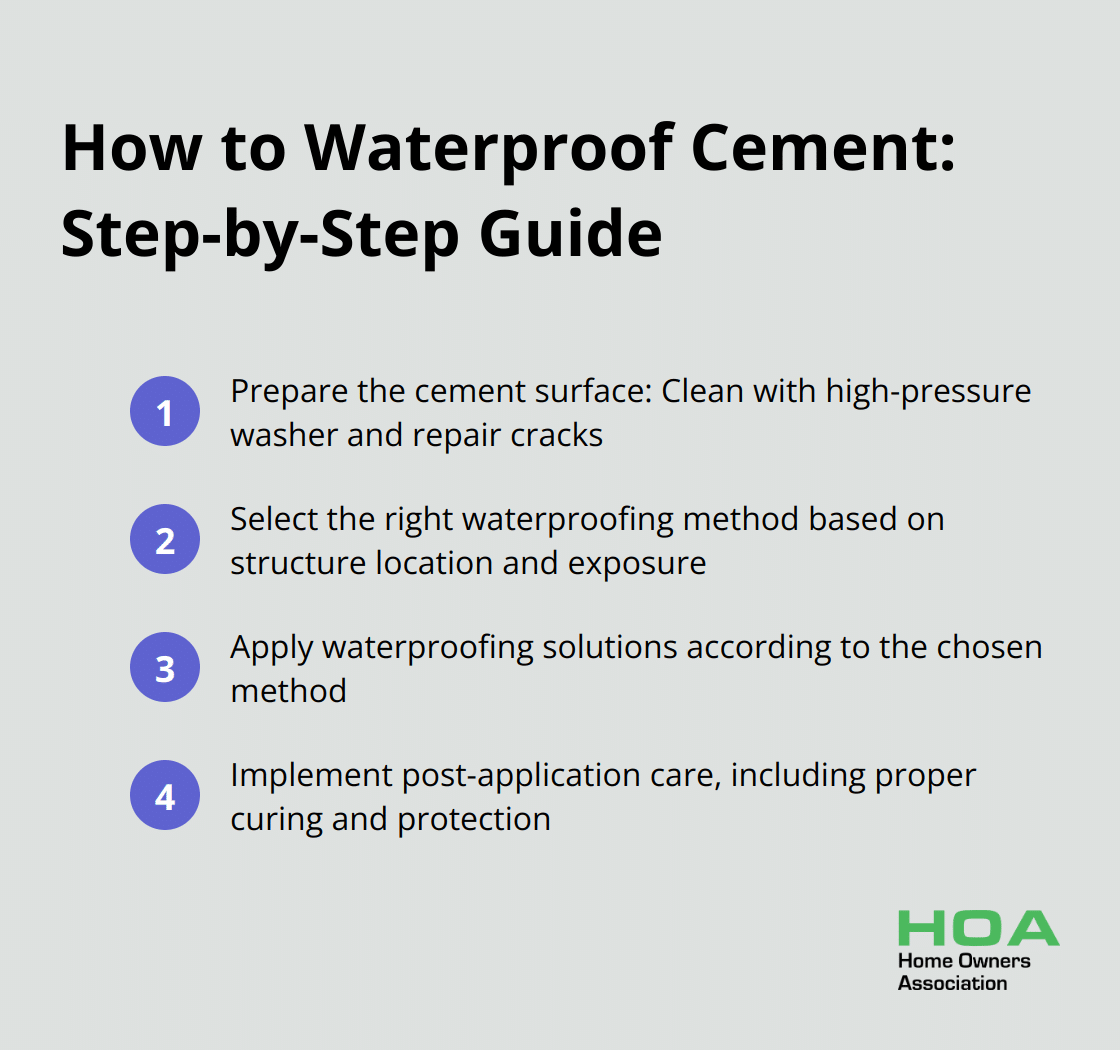

How to Waterproof Cement: A Step-by-Step Guide

Prepare the Cement Surface

The first step in any waterproofing project is thorough surface preparation. Clean the cement surface with a high-pressure washer (try to achieve at least 3000 PSI). This removes dirt, debris, and loose cement particles that could interfere with the waterproofing process.

Inspect the surface for cracks or damage. Fill cracks wider than 0.3mm with a suitable concrete repair mortar. For smaller cracks, use a fine cement slurry or epoxy injections. Even tiny cracks can lead to significant water infiltration over time.

Select the Right Waterproofing Method

Choose the appropriate waterproofing method based on the structure’s location, exposure level, and intended use. For example, basement walls facing hydrostatic pressure might benefit from an external membrane system, while a concrete roof might require a liquid-applied waterproofing membrane.

Consider the climate as well. In areas with extreme temperature fluctuations (like parts of Western Australia), flexible waterproofing systems are often more effective. These can accommodate the expansion and contraction of the concrete without cracking.

Apply Waterproofing Solutions

When applying surface sealants, use a low-pressure sprayer for even coverage. Apply two coats, with the second coat perpendicular to the first for optimal protection. The Australian Concrete Repair Association recommends a minimum 4-hour wait between coats in normal conditions.

For crystalline waterproofing, mix the product according to the manufacturer’s instructions and apply with a stiff brush or spray equipment. The key is to achieve a consistent, thick coating. Many successful projects have used two coats, applied at right angles to each other.

If you’re using an external membrane, ensure it’s fully adhered to the concrete surface. Pay extra attention to corners and joints, as these are common weak points. Use reinforcing tape at these locations for added protection.

Implement Post-Application Care

After application, proper curing is essential for the waterproofing system to reach its full potential. Keep the treated surface damp for at least 48 hours, or as specified by the product manufacturer. This is particularly important in hot, dry climates like central Australia.

Protect the newly waterproofed surface from rain, foot traffic, and other disturbances during the curing period. For below-grade applications, wait at least 7 days before backfilling to ensure the waterproofing system has fully set.

Regular inspections maintain the effectiveness of your waterproofing system. Annual checks are recommended, with close attention to areas prone to water exposure. Prompt repairs of any damage can prevent minor issues from becoming major problems.

While DIY is possible for some projects, complex waterproofing tasks often benefit from professional expertise. Qualified contractors can ensure your waterproofing project is completed to the highest standards.

Final Thoughts

Cement waterproofing protects your property from water damage and extends its lifespan. We explored various effective methods, including surface-applied sealants, integral admixtures, external membranes, and crystalline technology. Proper application and ongoing maintenance are essential for successful waterproofing.

Cement waterproofing prevents costly water damage, extends structural lifespan, and improves energy efficiency. The Home Owners Association offers valuable resources and support for your waterproofing projects in Melbourne. Our members receive expert advice, access to trade pricing, and personalised guidance for successful home improvements.

Complex waterproofing applications often require professional expertise. Proper planning and execution are vital for lasting protection against water infiltration (regardless of project size). You invest in your property’s future when you implement effective cement waterproofing techniques.