Australia’s unique climate presents both opportunities and challenges for home brewers. High temperatures and humidity levels require specific techniques that differ from traditional brewing methods.

We at Home Owners Association have compiled proven home brew tips Australia brewers swear by. These methods help you create exceptional beer despite the demanding weather conditions across the continent.

Essential Home Brewing Equipment for Australian Conditions

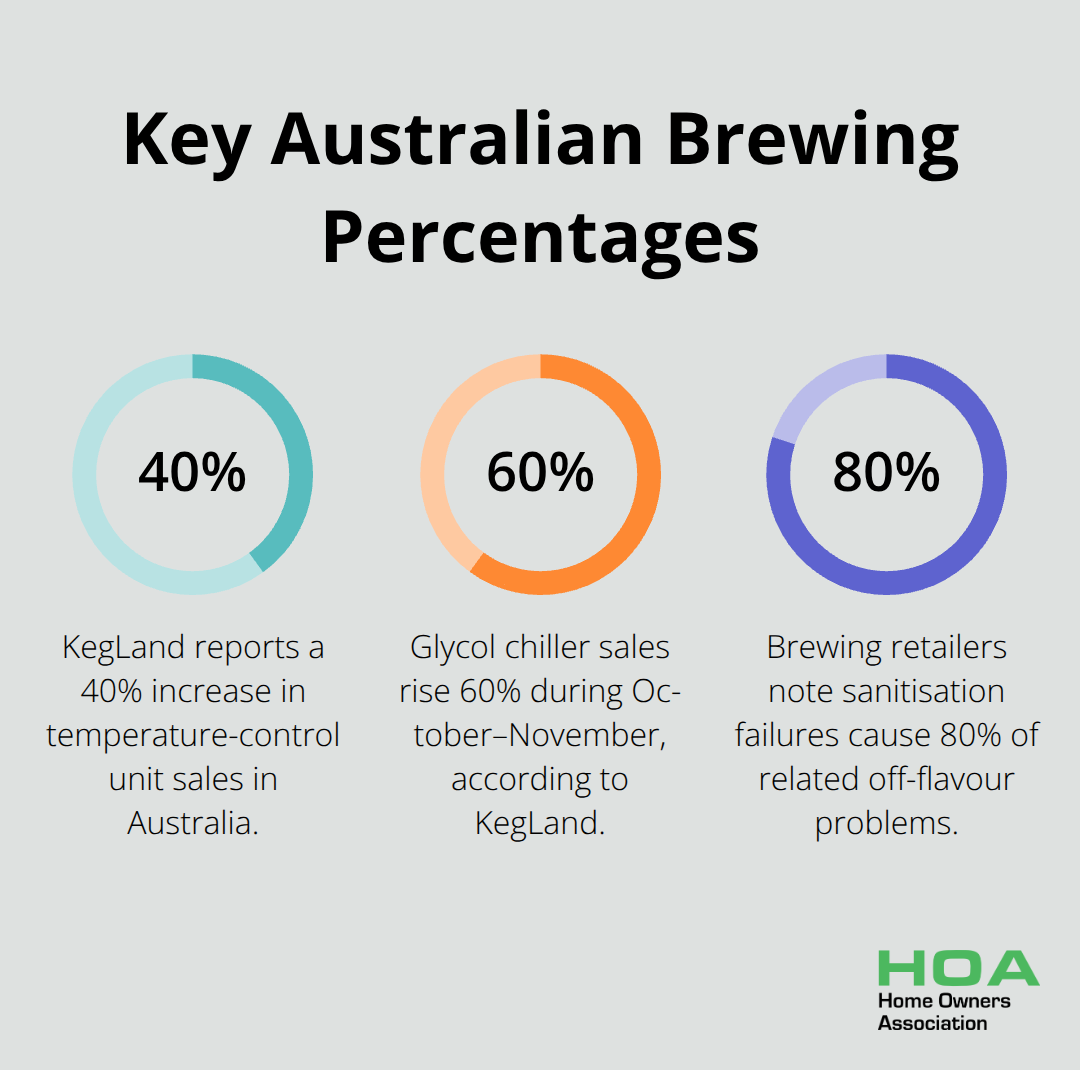

Australian temperatures regularly exceed 30°C during summer months, which makes standard fermentation vessels inadequate for consistent beer production. Stainless steel conical fermenters with insulated jackets provide superior temperature stability compared to plastic buckets that fail in extreme heat. The Grainfather system offers temperature-controlled processes that maintain optimal fermentation ranges between 18-22°C even when ambient temperatures soar above 35°C. KegLand reports a 40% increase in sales of temperature control units as Australian brewers recognise their necessity rather than luxury status.

Temperature Control Systems That Deliver Results

Fermentation refrigerators with digital controllers prevent the wild temperature swings that destroy batches during Australian summers. Inkbird temperature controllers paired with chest freezers create consistent environments that commercial breweries rely on. Heat mats become essential during winter months in southern regions where temperatures drop below optimal fermentation ranges. These systems cost between $300-600 but save hundreds of dollars in ruined batches (a worthwhile investment for serious brewers).

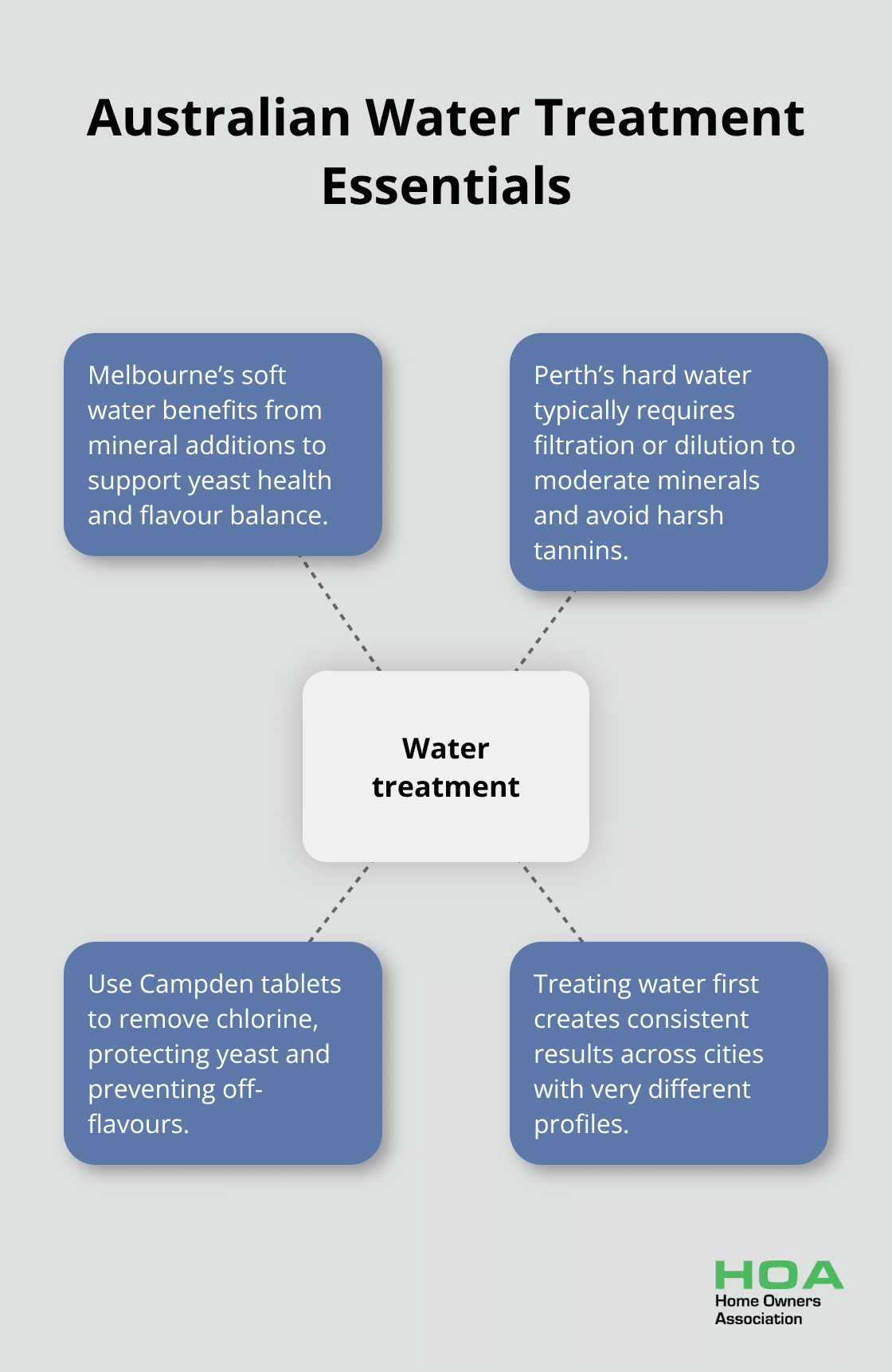

Water Treatment and Regional Variations

Australian water varies dramatically between regions, with Melbourne’s soft water that requires mineral additions while Perth’s hard water needs filtration. Campden tablets remove chlorine from tap water, which kills yeast and creates off-flavours that ruin entire batches. Water treatment becomes the foundation of successful home brew production across different Australian cities.

Quality Ingredient Sources

Local suppliers like Grain and Grape in Melbourne stock fresh Australian malts that outperform imported alternatives in hot climates. Quality Australian hops like Galaxy and Ella provide unique flavour profiles unavailable elsewhere, but require proper storage in freezers to maintain potency in high humidity conditions. Fresh ingredients make the difference between average and exceptional home brew results (especially in challenging Australian conditions).

The next phase of successful home brew production focuses on the actual process itself, where proper technique transforms quality ingredients into exceptional beer.

Step-by-Step Brewing Process for Beginners

Australian home brewers waste countless batches because they skip fundamental preparation steps that determine success or failure. Start with extract brewing kits rather than all-grain methods, as extract brewing produces consistent results while you master fermentation basics. Choose darker beer styles like porters or stouts for your first attempts because these styles hide minor flavour imperfections that lighter beers expose mercilessly.

Recipe Selection for Australian Conditions

Australian Pale Ale recipes work exceptionally well in local conditions and require Galaxy hops at 20 grams per 23-litre batch with Australian ale yeast that tolerates temperature fluctuations better than imported strains. Fresh wort kits eliminate boiling steps and reduce brewing time from eight hours to three hours, making them perfect for beginners who want quick results. Temperature-sensitive lager styles fail consistently in Australian conditions unless you invest in refrigeration equipment, so stick with ale recipes that ferment successfully between 20-24°C.

Fermentation Management That Prevents Disasters

Fermentation temperatures above 25°C create fusel alcohols that taste like paint thinner and ruin entire batches permanently. Digital thermometers with alarms prevent these disasters and alert you when temperatures exceed safe ranges during hot Australian nights. Primary fermentation takes 5-7 days for ales, and specific gravity readings should drop from 1.045 to 1.010 for complete fermentation. Hydrometers cost $15 but save hundreds of dollars in wasted ingredients (they confirm fermentation completion before bottling begins).

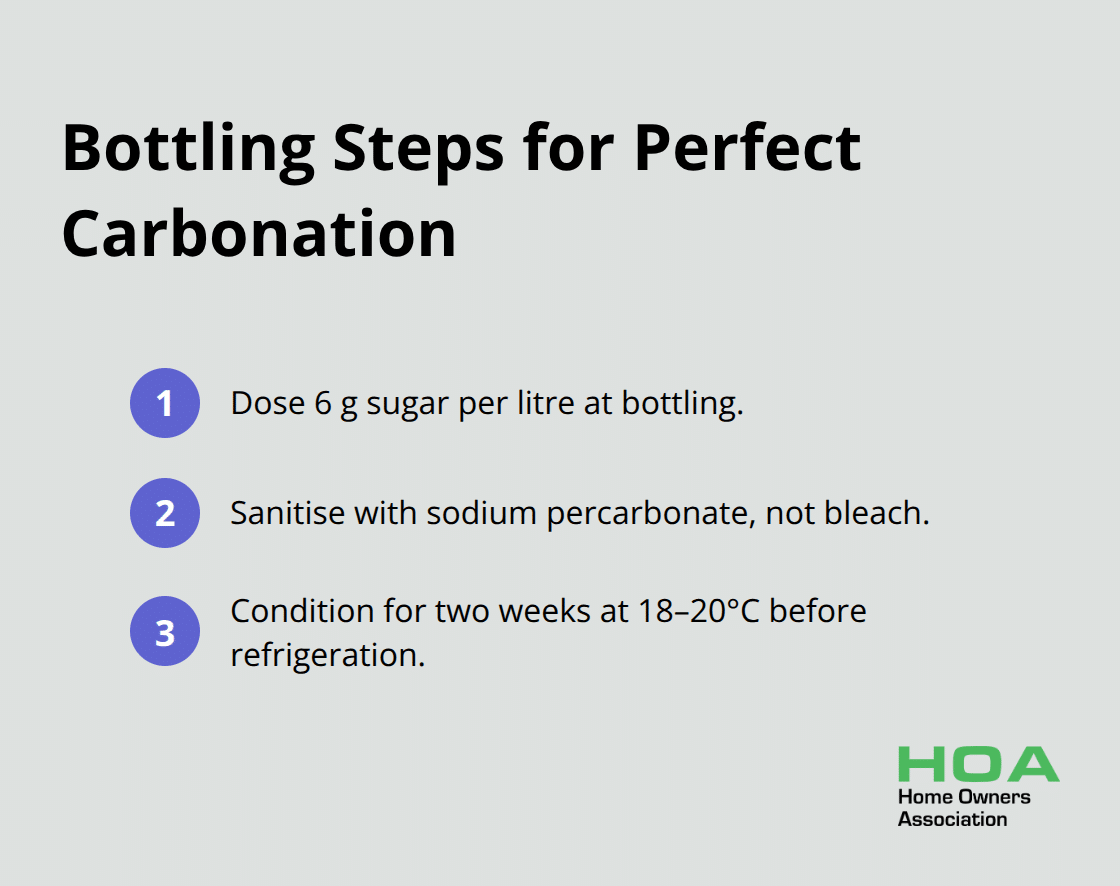

Bottling Techniques for Perfect Carbonation

Add exactly 6 grams of sugar per litre during bottling to achieve proper carbonation levels without creating bottle bombs that explode from over-pressurisation. Sanitise bottles with sodium percarbonate solution rather than bleach, which leaves residual flavours that contaminate finished beer. Condition bottles at 18-20°C for two weeks minimum before refrigeration, as cooler temperatures slow carbonation and produce flat beer that disappoints everyone.

Even perfect technique sometimes produces unexpected results, which leads experienced brewers to develop advanced troubleshooting skills that separate amateur attempts from professional-quality results.

Advanced Techniques That Solve Australian Brewing Challenges

Melbourne water contains low mineral levels compared to other Australian cities, which means identical grain bills produce completely different beer flavours across Australia. Reduce base malt by 10-15% when you brew with hard water above 200ppm total dissolved solids, as excessive minerals extract harsh tannins that create astringent off-flavours. Sydney brewers add 2 grams of gypsum per 23 litres to enhance hop character, while Perth brewers dilute their water with 30% reverse osmosis water to prevent mineral overload. Water test strips cost $20 and reveal exactly which adjustments your local water requires for specific beer styles.

Climate-Specific Problem Prevention

Wild temperature swings during Australian spring create stuck fermentations that stop at 1.020 gravity instead of completion levels at 1.010. Pitch double yeast quantities during temperature-unstable periods and maintain fermentation chambers between 19-21°C with glycol chillers that KegLand reports sell 60% more during October-November months. Diacetyl off-flavours taste like butter and occur when fermentation temperatures exceed 24°C for more than 12 hours.

These problems disappear with consistent temperature control, but require immediate action once you detect them through taste tests after primary fermentation completes.

Recipe Enhancement Methods That Work

Replace 20% of base malt with Vienna malt to add complexity without modification of fermentation requirements, as Vienna malt performs better in Australian heat than Munich alternatives. Dry hop additions at 4 grams per litre during the final three days of fermentation maximise aroma extraction while they prevent grassy off-flavours from extended contact time. Australian Galaxy hops added at flameout create tropical fruit characteristics that complement local water profiles better than imported Cascade varieties (which often clash with mineral-heavy Australian water). Fermentation temperature ramps from 18°C to 22°C over five days develop complex esters that distinguish professional-quality results from basic homebrew attempts.

Advanced Troubleshooting Solutions

Acetaldehyde off-flavours create green apple tastes that indicate incomplete fermentation or premature bottling before yeast finishes conversion of all sugars. Test final gravity readings three days apart to confirm fermentation completion, as rushed bottling creates these persistent off-flavours that ruin entire batches. Phenolic off-flavours taste medicinal and result from wild yeast contamination or chlorine exposure during the brewing process (sanitisation failures cause 80% of these problems according to brewing supply retailers).

Final Thoughts

Successful home brewers in Australia master temperature control, source quality local ingredients, and apply consistent techniques. These home brew tips Australia brewers depend on prevent common failures that waste time and money during extreme weather conditions. Extract kits and darker beer styles provide the best foundation for beginners who want reliable results.

Temperature control systems cost $300-600 but save hundreds of dollars in ruined batches. Digital thermometers with alarms prevent fermentation disasters during hot Australian nights. Water treatment becomes essential when you brew across different Australian regions with varying mineral profiles.

Build skills through consistent practice rather than complex recipes that overwhelm beginners. Join local clubs for feedback and troubleshooting advice from experienced brewers who understand regional challenges. We at Home Owners Association connect you with quality equipment suppliers and provide expert guidance for successful home projects.