At Home Owners Association, we understand the importance of protecting your property from water damage. Waterproofing foam is a modern solution that offers superior protection compared to traditional methods.

This versatile material can be applied to various surfaces, creating a durable barrier against moisture intrusion. In this guide, we’ll walk you through the effective use of waterproofing foam to safeguard your home.

What Is Waterproofing Foam?

Waterproofing foam is a specialised sealant that creates a barrier against moisture intrusion in buildings. Its use has increased significantly across Australia, particularly in areas prone to heavy rainfall or flooding. However, it’s important to note that RetroFoam can break apart under pressure, allowing water to escape potentially preventing more severe water damage to the home’s structure.

Composition and Application

This innovative product typically consists of polyurethane or silicone-based compounds. When applied, it expands to fill gaps and cracks, forming a tight seal that prevents water from seeping through. The foam’s expansion rate can vary, with some products expanding up to 30 times their original volume.

Types of Waterproofing Foam

Two main types of waterproofing foam exist: spray foam and injectable foam. Spray foam is applied using a canister or gun and works well for larger surface areas. Injectable foam excels at filling specific cracks or voids in walls or foundations.

High-density closed-cell foam proves particularly effective for waterproofing. Compared to open cell foam, closed cell foam has superior waterproofing capabilities. Its high density stops water from entering.

Advantages Over Traditional Methods

Waterproofing foam offers several benefits over conventional waterproofing techniques:

- Flexibility: Its ability to expand and conform to irregular shapes makes it superior to rigid waterproofing materials. This flexibility allows it to maintain its seal even as buildings settle or shift over time.

- Faster Application: The application process takes less time and labour than traditional methods like membrane installation. A professional can typically waterproof an average-sized basement in a day using foam (compared to several days for other methods).

- Energy Efficiency: Waterproofing foam acts as an insulator, potentially reducing energy costs.

Professional Application

While waterproofing foam is highly effective, proper application is essential. Incorrect use can lead to over-expansion, potentially damaging surrounding structures. For large-scale waterproofing projects, consulting with a professional is always recommended.

As we move forward, let’s explore the necessary preparations for applying waterproofing foam effectively.

Preparing Your Space for Waterproofing Foam

Evaluating Your Waterproofing Needs

Start with a comprehensive inspection of the area you plan to waterproof. Look for existing water damage, cracks, or potential entry points for moisture. Pay special attention to corners, joints, and areas around pipes or fixtures. A study by the Australian Building Codes Board identified ingress of sub-surface water to buildings as the main cause of waterproofing defects in Class 2 to 9 buildings.

Measure the area you need to cover and note any challenging spots that might require special attention. This step will help you determine how much foam you’ll need and identify areas that might benefit from additional reinforcement.

Essential Tools and Materials

After you’ve assessed the area, gather your supplies. Here’s what you’ll typically need:

- Waterproofing foam (spray or injectable, depending on your project)

- Foam applicator gun (for better control and precision)

- Cleaning supplies (brushes, rags, and a suitable solvent)

- Protective sheeting (to cover surrounding areas)

- Putty knife or scraper (for smoothing and removing excess foam)

- Moisture meter (to check surface dampness before application)

Check the expiration dates on your foam canisters. Fresh product ensures better expansion and adhesion.

Safety First: Protective Measures

Waterproofing foam contains chemicals that require careful handling. Prioritise your safety with these precautions:

- Wear a respirator mask rated for organic vapours

- Use chemical-resistant gloves to protect your skin

- Don safety goggles to shield your eyes from splashes

- Wear old clothes or disposable coveralls

Ensure proper ventilation in your work area. Open windows and use fans to circulate air. Safe Work Australia recommends that cooling towers should be designed, installed and maintained in accordance with AS/NZS 3666 – Air handling and water systems of buildings.

Surface Preparation

Clean the surface thoroughly to remove any dirt, dust, or debris. Use a suitable solvent to remove any grease or oil. Allow the surface to dry completely before application. (A moisture meter can help you determine if the surface is dry enough for foam application.)

Sand or roughen smooth surfaces to improve adhesion. Fill any large cracks or holes with an appropriate filler and allow it to cure before applying the foam.

Temperature Considerations

Check the ambient temperature and the temperature of the surface you’ll be treating. Most waterproofing foams work best when applied at temperatures between 5°C and 35°C (41°F to 95°F). (Application outside this range can affect the foam’s expansion and curing properties.)

Now that you’ve completed these preparatory steps, you’re ready to move on to the actual application process. In the next section, we’ll guide you through the step-by-step procedure for applying waterproofing foam effectively.

How to Apply Waterproofing Foam

Surface Preparation

Clean the surface thoroughly. Remove all dirt, dust, and debris with a wire brush or pressure washer. For stubborn stains or grease, use a degreaser. Allow the surface to dry completely before you proceed. The optimum value of moisture content of the base surface (9.7–9.8%) allowed obtaining the maximum adhesion of the coating to the base.

Foam Preparation

Shake the foam canister vigorously for at least 30 seconds to ensure proper mixing. If you use a two-component foam, mix it according to the manufacturer’s instructions. Attach the applicator nozzle or gun securely to prevent leaks.

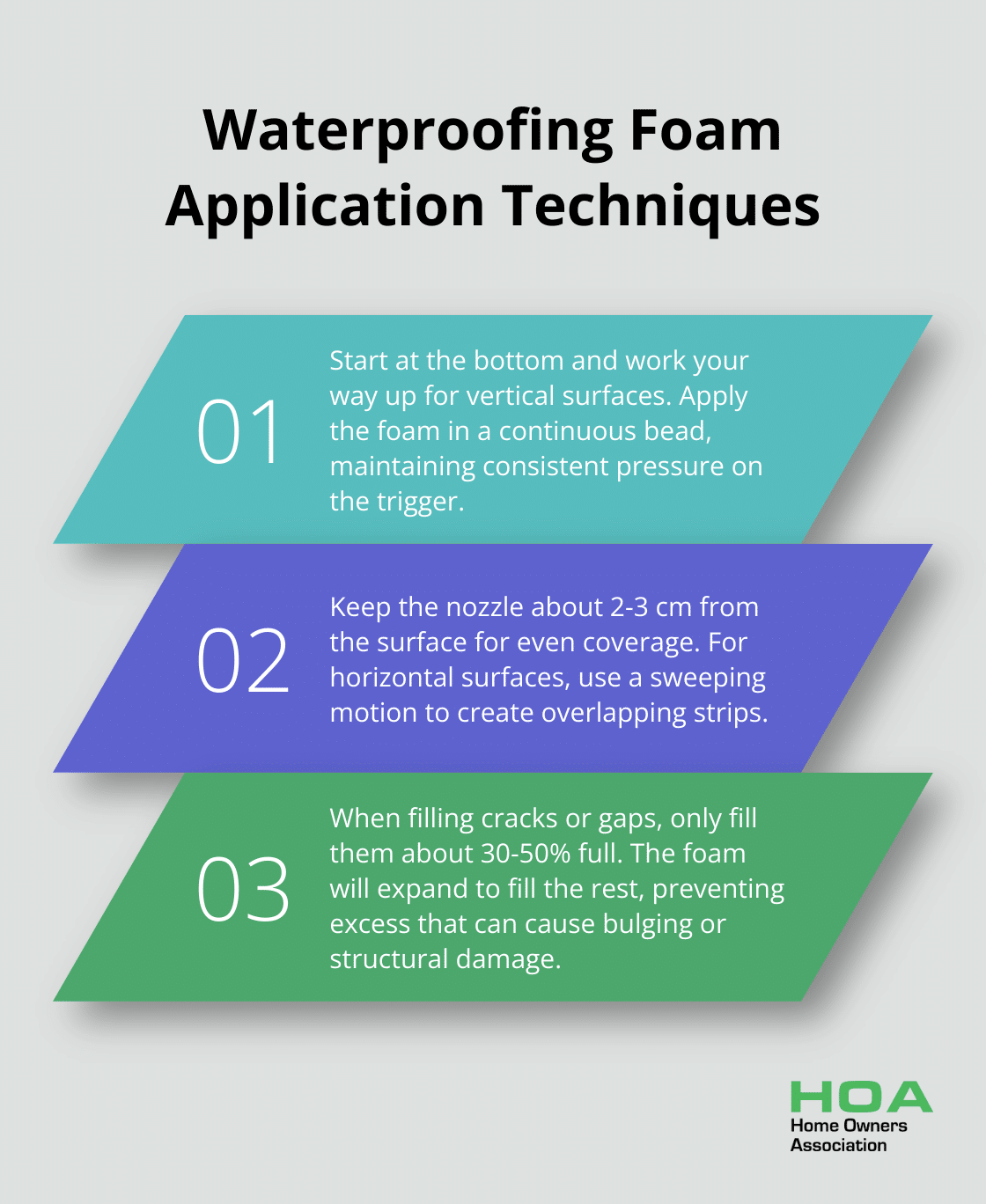

Application Techniques

Start at the bottom and work your way up for vertical surfaces. Apply the foam in a continuous bead, maintain consistent pressure on the trigger. Keep the nozzle about 2-3 cm from the surface for even coverage. For horizontal surfaces, use a sweeping motion to create overlapping strips.

When you fill cracks or gaps, only fill them about 30-50% full. The foam will expand to fill the rest. Excess foam can cause bulging or distortion of walls, ceilings, and other surfaces, as well as structural damage.

Surface-Specific Tips

For concrete surfaces, apply a thin layer first to improve adhesion. Allow this layer to become tacky before you apply the main coat. On metal surfaces, lightly scuff the area with sandpaper to create a better bonding surface.

For wood, ensure the surface is completely dry to prevent trapping moisture. Apply the foam in thinner layers to allow for proper curing throughout.

Curing and Drying

Most waterproofing foams become tack-free within 10-15 minutes and fully cure within 24 hours. However, these times can vary based on temperature and humidity. In cooler conditions, curing may take up to 48 hours.

During the curing process, keep the area protected from moisture and direct sunlight. Avoid touching or disturbing the foam as it cures to prevent compromising its waterproofing properties.

After full curing, inspect the application for any gaps or missed spots. Apply additional foam as needed to ensure complete coverage for maximum waterproofing effectiveness.

Final Thoughts

Waterproofing foam has transformed how we protect homes from moisture damage. Its versatility, easy application, and superior sealing properties make it an excellent choice for many projects. We recommend you follow the steps in this guide to apply waterproofing foam effectively and safeguard your property.

Proper preparation is essential for successful application. Clean and dry surfaces, appropriate safety gear, and the right tools will help you achieve the best results. Work methodically when applying the foam and avoid overfilling gaps to prevent expansion issues (allow sufficient time for curing).

For large-scale applications or complex structural issues, professional expertise might be necessary. At Home Owners Association, we can connect you with trusted waterproofing specialists in Melbourne. Understanding and properly using waterproofing foam will help you protect your home’s integrity and value for years to come.